In the cannabis industry, solvent-based extraction is crucial for commercial operation. These methods offer the economy and efficiency for producing highly potent cannabis products. A core component of modern cannabis extraction is a closed loop extraction system. A closed loop extractor has emerged as a superior technique among all extraction techniques. Here, we will explore the intricacies of closed loop extraction systems, how they work, their benefits, and more.

Sections

ToggleWhat Is Closed Loop Extraction?

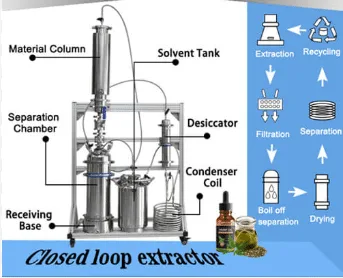

Closed loop extraction is an advanced method for solvent-based extraction of desired compounds from cannabis plant material. The system circulates solvent within a sealed system for maximum efficiency, purity, and safety. In a closed loop extractor, the solvent never comes in contact with the air, making the system highly efficient and minimizing risks by containing volatile solvents.

Closed Loop vs Open-Loop Extraction

Open-loop extraction is the traditional method of extraction in which solvents are exposed to the atmosphere during the extraction process. This system has potential safety hazards and solvent loss. Also, controlling parameters such as temperature and pressure is challenging. By contrast, a closed loop extraction system keeps solvents in a sealed environment, allowing precise control over the process while minimizing risks.

How Does a Closed Loop Extraction System Work?

A closed loop extractor is so efficient because it operates through a carefully designed series of steps, each crucial to producing high-quality extracts.

Let’s break down the process:

- Solvent Injection: Closed loop system extraction begins with introducing a solvent (such as butane or ethanol) from a pressurized tank into the system. The pressure and heat are adjusted depending on the type of solvent used.

- Extraction: The solvent passes through a column filled with plant material, dissolving and carrying the desired compounds. The solvent and desired compound mixture are fed into a different chamber for separation.

- Separation & Purification: The solvent-extract mixture is separated and purified, often using heat and vacuum pressure. Depending on the properties of the solvent, the filtration method varies.

- Solvent Recovery: In a closed loop system, the solvent is recaptured and condensed into liquid form for reuse. No separate purging is required, and the system is designed to recover all solvents.

- Final Product Collection: After solvent purging, the purified extract is collected and ready for further processing or packaging.

Key Components of a closed loop extractor:

- Solvent Tank: The chamber stores and supplies the solvent used in the extraction process. Typically, solvent tanks are made of stainless steel.

- Material Column: The chamber houses the cannabis plant material from which compounds are extracted.

- Recovery Tank: A complex setup with a heater, compressor, and vacuum pumps, it collects and condenses the used solvent for recycling.

- Vacuum Pump: They help in the separation and purification stages of the process.

Types of Closed Loop Extraction Systems

There are various closed loop extraction systems, but the two most widely used are closed loop BHO extractor and closed loop ethanol extractor. Let’s take a closer look at each type:

1. Closed Loop BHO Extractor

A closed loop BHO system uses butane as a solvent for extraction. It is a preferred method for extracting potent cannabis concentrates like wax and shatter from plant material. Due to its ability to extract full spectrum cannabinoids and terpenes, it produces highly potent and flavorful extracts.

A closed loop butane extractor operates under pressure and low temperature. As it uses butane in liquid form, it maintains a temperature of -40°F (-40°C), allowing for rapid extraction while maintaining the integrity of delicate compounds. Extractors favor this method for producing high-quality cannabis concentrates that preserves the plant’s natural flavor profile.

2. Closed Loop Ethanol Extraction

Hydrocarbons like butane are highly volatile, which makes the extraction process risky. The closed loop ethanol extraction method is used in various industries as an alternative. It is a versatile closed loop extraction system used in the pharmaceutical, nutraceutical, and food industries. The process uses ethanol, which is a safer and food-grade solvent. Additionally, the method is suitable for large-scale production as it is efficient, economical, and can extract a broad range of compounds, including cannabinoids and terpenes. If you want to create products for human consumption, closed loop ethanol extraction is ideal, as ethanol is generally recognized as a safe (GRAS) solvent.

Why Choose a Closed Loop Extraction System?

Compared to traditional cannabis extraction methods, a closed loop extraction system offers several advantages, from efficiency to cost-effectiveness.

1. Efficiency and Solvent Recovery

One of the core principles of designing closed loop extraction systems is to preserve solvents and recycle them. A closed loop extractor recycles solvents, which not only reduces operational costs but also minimizes environmental impact. With modern closed loop systems like the Root Sciences’ EFR – Unified Solution for Cold Processed Ethanol Extraction, producers can recover up to 99% of the solvent used. This can significantly cut down on waste and expenses associated with solvent replenishment.

2. Safety and Containment

Solvent-based extraction methods have a risk of solvent exposure and explosion. Closed loop extraction systems completely isolate volatile solvents, dramatically reducing the risk of leaks, spills, or explosions. Furthermore, these systems ensure compliance with strict safety regulations, making it easier for businesses to obtain and maintain necessary permits and certifications.

3. Purity and Quality of Extracts

Due to the sealed environment of a closed loop extraction system, there are no contaminants during the extraction process. The result is purer extracts with higher potency and better preservation of volatile compounds like terpenes. This makes closed loop extraction crucial for industries like pharmaceuticals or high-end cannabis concentrates.

4. Cost-Effectiveness

Although the initial investment in a closed loop extraction system may be higher than in traditional methods, the benefits are substantial when you compare the long-term cost savings. The ability to reuse solvents drastically cuts ongoing operational expenses. Additionally, these systems have higher extraction efficiency, meaning less raw material is needed to produce the same amount of extract, further contributing to cost savings.

How to Use a Closed Loop Extractor Safely

Understanding how to use a closed loop extractor is crucial to benefit fully. It includes operating the system and best practices for maintaining safety and product quality.

Here are some key considerations:

Proper Setup and Operation

A closed loop extractor requires a leak-free setup to operate efficiently. That’s why you must ensure the system is well set up with no loose connections or any signs of wear or damage. Thoroughly inspect all connections to ensure they are tightened to prevent leaks. Depending on the system manufacturer, use approved high-grade solvents and compatible equipment designed for closed loop extraction. It will ensure the process’s integrity and the final product’s quality.

Essential Safety Measures

Safety should always be the top priority when operating, particularly with a closed loop BHO extractor. The extraction facility should be well-ventilated and equipped with safety features such as gas detectors and fire suppression systems. Only trained operators must handle pressurized gases. Follow all relevant industry regulations and best practices to ensure safety.

Common Mistakes to Avoid

Even with the advanced safety features of a closed loop extraction system, there is room for human error; avoid these common mistakes:

- Do not overfill the material column, as it can cause clogs and reduce efficiency.

- Even minor neglect in monitoring pressure levels throughout the process can result in equipment failure or compromised extract quality.

- Never use subpar solvents to save cost, as it will affect the final product and damage the equipment.

Conclusion

The cannabis extraction industry is evolving, with modern closed loop extraction being adopted for efficiency, safety, and product quality. A closed loop extractor can recycle solvents, maintain a controlled environment, and produce high-purity cannabis extract. If you are concerned about the high initial investment, remember that the long-term advantages of safety, efficiency, and product quality far outweigh the costs.