For a producer in the cannabis industry, one of the goals is to maximize extraction efficiency. Cannabis extraction is the process of transforming raw plant material into concentrated forms of cannabinoids and terpenes. The cannabis extraction yield is a crucial aspect of production directly associated with the quality of the final product and the profitability of cannabis businesses.

In this article, we will explore ways to improve cannabis extraction efficiency. Here, we delve into the intricacies of cannabis extraction, exploring methods to optimize efficiency, boost yields, and maintain the highest purity standards in the extraction process.

Sections

ToggleWhat Are Cannabis Extraction Yields?

Cannabis extraction yield is the amount of the desirable cannabinoids and terpenes recovered from the raw plant material during the extraction process. Simply, it measures how effectively the chosen extraction method pulls out the valuable compounds from the cannabis plant.

The end goal of any cannabis production company is to ensure higher yields for several reasons:

- Increase Revenue: Revenue is the ultimate driving factor behind a business’s success. A higher yield means more cannabis products can be produced from the same amount of raw material, directly impacting the bottom line.

- Cost Efficiency: Maximizing cannabis extraction yield also ensures that every bit of valuable raw material is utilized. It improves production, reduces waste, and boosts the cost-effectiveness of operations.

- Better Resource Utilization: Growing and curing cannabis plants is not easy. Efficient extraction processes make the most of limited resources, including plant material, solvents, and energy.

- Competitive Advantage: If, as a producer, you can keep the cannabis extraction yield higher, you can offer more competitive pricing or maintain better profit margins.

Therefore, as a producer in the cannabis industry, understanding and optimizing extraction efficiency becomes crucial to thrive in this competitive market.

How to Calculate Extraction Efficiency

Before optimizing the cannabis extraction processes for maximum efficiency, you have to calculate the existing cannabis extraction yield. Calculating extraction efficiency is essential to gauge your processing methods’ effectiveness and identify areas for improvement.

The basic formula for calculating extraction efficiency is:

Extraction Efficiency (%) = (Mass of Extract Obtained / Mass of Input Material) × 100

However, this is the most straightforward calculation, focusing on the materials’ mass. In cannabis product manufacturing, the revenue depends on the desired compound yield.

Therefore, a more accurate assessment is based on the concentration of desired compounds in both the input and final extract.

We recommend using this formula for a more comprehensive calculation:

Extraction Efficiency (%) = (Mass of Extract × Concentration of Desired Compound in Extract) / (Mass of Input Material × Concentration of Desired Compound in Input Material) × 100

Example calculation:

Let’s say a producer is using 1000g of cannabis biomass that has 10% CBD content. The output from this content is 80g of cannabis CBD oil with 80% CBD content.

If we calculate the extraction efficiency based on a basic formula, it will be:

Extraction Efficiency (%) = (80g / 1000g) x 100 = 8%

But this is wrong.

The accurate extraction efficiency will be:

Extraction Efficiency = (80g × 0.80) / (1000g × 0.10) × 100 = 64%

This means 64% of the available CBD in the input material was successfully extracted.

The Significance of Extraction Efficiency

Do not think that improving extraction efficiency is only about increasing yields; it has far-reaching implications for the entire production process and business model. Here are the crucial aspects of cannabis processing and production affected by the extraction efficiency:

- Minimizes waste: The more efficiency, the less will be the waste. Efficient extraction processes ensure that more valuable compounds are extracted, reducing the amount of potentially useful material that goes to waste.

- Maximum use of raw materials: Cannabis and hemp plants are hard to cultivate and process, which requires serious investment. Producers can make the most of their raw material investments by extracting more from each batch of plant material.

- Improves cost-efficiency: Higher efficiency means more cannabis products can be produced from less input. It directly impacts the cost per unit of the final product.

- Boosts Profitability: Increased cannabis extraction yield and reduced waste improve producers’ profit margins. It also enables them to offer more competitive pricing.

- Supports Sustainability: Efficient processes typically require less energy and fewer resources, aligning with sustainability goals. Cannabis and hemp cultivation carbon footprint can be significantly reduced by improving yields.

Depending on the cannabis extraction method you utilize, you can take steps to boost yield and improve efficiency.

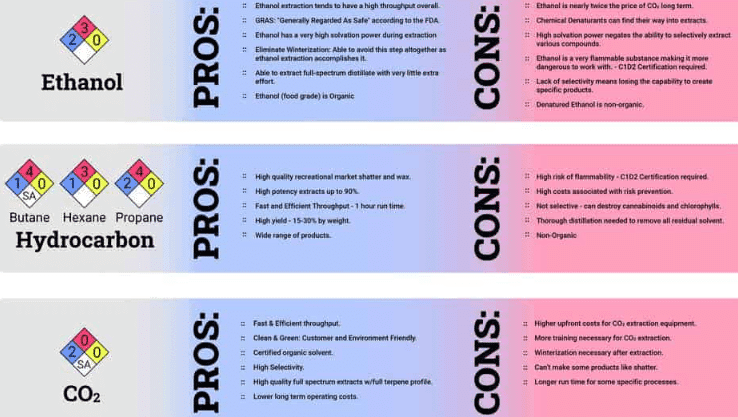

Cannabis Extraction Methods: Hydrocarbon, Ethanol, and CO2

Here, we look at the three most widely used cannabis extraction methods and how their efficiency and yield can be improved.

1. Hydrocarbon Extraction

This cannabis extraction method uses hydrocarbons like butane or propane as solvents to extract cannabinoids and terpenes.

Pros:

- Hydrocarbons have high efficiency in extracting a full spectrum of cannabinoids and terpenes

- Capable of producing high-purity cannabis extracts with minimal post-processing, further improving yields

Cons:

- Residual solvent contamination can affect extraction efficiency if not properly purged

- Higher investment for extraction due to flammable solvents

How to Improve Yields:

Hydrocarbons are volatile, so producers can improve extraction efficiency by optimizing solvent temperature and pressure. Also, using closed-loop systems like those offered by Root Sciences can help recover and reuse solvents effectively.

2. Ethanol Extraction

This method uses ethanol to extract cannabinoids and other compounds from plant material.

Pros:

- Ethanol is the most suitable solvent, capable of processing large volumes efficiently

- Relatively safe compared to hydrocarbon extraction, reducing the production cost

Cons:

- Can co-extract unwanted compounds like chlorophyll, requiring additional purification

- It may not be as efficient in extracting specific terpenes due to their volatility

How to Improve Yields:

Producers can boost the efficiency of ethanol extraction by reducing the temperature of ethanol. Chilled ethanol does not extract chlorophyll, proving the extraction yield.

3. CO2 Extraction

This method uses pressurized carbon dioxide in a supercritical state to extract cannabinoids and terpenes.

Pros:

- Highly efficient to target specific compounds as selective extraction is possible by adjusting temperature and pressure

- There is no residual solvent concern as CO2 evaporates completely

Cons:

- Higher initial equipment costs

- It can be less efficient in extracting volatile terpenes

How to Improve Yields:

Supercritical CO2 is not easy to maintain. Producers should invest in modern equipment like Root Sciences CO2 extraction equipment that allows fine-tuning pressure and temperature parameters for specific cannabinoid profiles. Also, implementing fractionation techniques to separate different compounds during extraction can improve yield.

How to Improve Efficiency in Extraction Processes

Regardless of the extraction method, you can take some measures to improve the efficiency of the extraction processes. It includes:

- Optimize Parameters: Research and adjust temperature, pressure, and flow rates for maximum efficiency during extraction.

- Pre-Treatment of Raw Materials: Another way to improve cannabis extraction yield is to dry and grind material for increased surface area.

- Regular Equipment Maintenance: Ensure all equipment works optimally efficiently and functions optimally to ensure you get all the production value.

- Utilize Automation: Implement automated systems for consistent, precise control over the extraction processes.

- Solvent Recovery Systems: Use efficient recycling systems to minimize solvent loss and reduce production costs.

How to Improve Extraction Efficiency

Let’s explore methods of improving extraction efficiency, which requires a multifaceted approach that includes:

- Optimize extraction parameters: Depending on the extraction method, you must ensure that a set of parameters is fine-tuned for maximum efficiency. For example, CO2 extraction requires adjusting pressure and temperature to target specific compounds. Even a fraction of a drop or increase in temperature or pressure can significantly impact efficiency and selectivity.

- Quality of raw material: Cannabis extraction yield depends on the quality and preparation of the cannabis or hemp biomass. Properly cured and ground material with a consistent moisture content will yield better results. Producers should implement strict quality control measures to ensure that the biomass used in production is high quality.

- Equipment selection and maintenance: While upfront investment can be high to set up quality cannabis extraction equipment, it is worthwhile in the long run. Also, it must be adequately maintained through regular cleaning and calibration to ensure consistent performance and prevent efficiency losses due to equipment issues.

- Solvent selection and recycling: If you use solvent-based extraction methods, choosing the suitable solvent and implementing efficient recycling systems can dramatically improve efficiency and reduce costs.

- Process integration: Designing an integrated process flow that minimizes material handling and transfer is crucial for large-scale production efficiency. This might include implementing inline winterization or other post-processing steps.

Techniques to Maximize Extraction Efficiency

To further enhance cannabis extraction efficiency at the industrial level, here are some advanced techniques that can help:

- Ultrasonic-Assisted Extraction: Using ultrasonic waves instead of a burner for heat can increase the mass transfer of cannabinoids from plant material to solvent, potentially increasing yields.

- Supercritical Fluid Extraction with Co-Solvents: To improve the efficiency of the CO2 extraction method, producers can add small amounts of co-solvents to enhance the extraction of specific compounds.

- Continuous Flow Extraction: This method allows for constant extraction from cannabis raw material. It can be more efficient than batch processing for large-scale operations.

- Cryo-Milling: Grinding plant material at very low temperatures can preserve volatile terpenes and increase overall extraction efficiency.

- Inline Winterization: Winterization is the process of removing waxes, fats, and lipids. Inline winterization as part of the extraction process, rather than as a separate step, can improve overall efficiency and reduce processing time.

- Advanced Filtration Techniques: Multi-stage filtration or centrifugal partition chromatography can improve the purity of cannabis extracts without sacrificing yield.

With the development of technology, automation is becoming an integral part of maximizing the efficiency of cannabis extraction. Modern extraction equipment often has sophisticated control systems that maintain precise parameters throughout extraction. For example, Root Sciences’ 20.LE CO₂ Extractor CO2 Extraction Equipment has efficiently produces full-spectrum oils, terpenes, and cannabinoid-rich extracts. It features automated, user-friendly controls for consistent performance. Designed for both craft and commercial use, it ensures reliable and high-quality extraction.

Ensuring Purity Alongside Maximized Yield

Do not discount purity to maximize cannabis extraction yield. If you are flexible with quality control, you might have a high yield but low purity. A balance is mandatory for producing high-quality cannabis extracts. Here are some steps to take:

- Winterization: Winterization is the process of removing fats, lipids, and waxes from the extract. While it can slightly reduce overall yield, it significantly improves purity and quality.

- Distillation: Fractional distillation can further purify cannabis extracts, separating individual cannabinoids based on their boiling points. This process can produce highly pure single-cannabinoid extracts.

- Chromatography: For the highest purity levels, particularly for medical applications, preparative chromatography can isolate specific compounds.

- Solvent removal: It is essential to obliterate any residual solvents. It has a significant impact on product safety and purity. With methods such as multiple stages of filtration that include activated carbon or silica gel, producers can remove most unwanted plant pigments and other contaminants.

- Quality testing: Implementing rigorous testing protocols at various stages of the extraction and purification process will ensure that your products always meet purity standards.

Minimizing contaminants should be a priority for purity. This includes removing residual solvents and pesticides, heavy metals, and microbial contaminants.

Conclusion

Achieving maximum extraction efficiency in cannabis processing can be challenging but is a crucial endeavor. It will require a deep understanding of extraction methods, careful optimization of process parameters, and implementing advanced techniques.

With increasing demand for cannabis products, producers who can consistently achieve high cannabis extraction efficiency while maintaining product purity will be best positioned for success. Root Sciences can help you with best-in-class cannabis extraction equipment that balances efficiency, yield, and purity, consistently producing high-quality extracts that can meet quality standards.