The extraction of oil is the core process for cannabis-based production. The choice of the extraction technique plays a crucial role in product development as it affects the outcome, purity, and economy. As cannabis extraction methods become increasingly sophisticated, manufacturers have several options to choose from, allowing them to produce a wide range of concentrates and infused products.

In this article, we explore the most widely used Cannabis extraction methods, their pros and cons, and how they compare efficiency, safety, and end-product quality.

Sections

ToggleTypes of Cannabis Extraction Methods

1. Solvent-Based Extraction Methods

As the term suggests, these methods use a solvent to extract cannabinoids and terpenes from cannabis plants. More suitable for commercial operations, these methods are generally more efficient and scalable than solventless methods but require careful handling and post-processing.

a) CO2 Extraction

Also known as supercritical CO2 extraction, this method uses heated and pressurized CO2 gas for highly advanced cannabis extraction. This method requires specialized equipment to store and maintain CO2 in a supercritical state.

Here are the steps involved in this extraction process:

- CO₂ is pressurized above 73.8 bar (1,071 psi) and heated to 31.1°C (87.98°F) in a specialized chamber. CO2 reaches a “supercritical” state at this pressure and heat, exhibiting properties of both a liquid and a gas.

- Supercritical CO2 is then passed through cannabis material, dissolving the trichomes and cannabinoids and separating it from the plant matter.

- The CO₂-cannabinoid mixture is then separated in another chamber. Here, the pressure is decreased, resulting in CO2 returning to its gaseous state and leaving behind the extracted compounds.

Advantages:

- CO2 extraction produces a clean extract with no residual solvents

- The extraction method is highly customizable, with selective extraction of specific compounds

- As CO2 is non-toxic and can be recycled, making the process highly environmentally friendly

- Can be easily scaled for commercial production

Disadvantages:

- Requires expensive, specialized equipment

- The extraction process is longer compared to some other methods

- Due to involvement of heat can degrade some terpenes

We have detailed the CO2 extraction process here.

b) Hydrocarbon Extraction (Butane & Propane – BHO/PHO)

One of the most widely commercialized cannabis extraction methods is hydrocarbon extraction. This method uses solvents like butane and propane to extract cannabinoids and terpenes from cannabis plant material. The process typically involves:

- The process starts by cooling down the hydrocarbon to improve its efficiency, then passing it through cannabis material.

- In a chamber, cannabis plant material is soaked in chilled hydrocarbon, which gradually dissolves cannabinoids, terpenes, and other compounds.

- The solvent-extract mixture is collected and then purged of residual hydrocarbons using heat and vacuum.

- Additional purification steps like winterization and distillation may be required depending on the solvent residue or the level of purity needed.

Advantages:

- High efficiency and ability to extract a wide range of compounds

- Excellent at preserving terpene profiles due to no use of heat

- Extracts are more flavorful

- Relatively cost-effective compared to CO₂ extraction

- It can produce a variety of consistencies (shatter, wax, budder, etc.).

Disadvantages:

- Hydrocarbon solvents are highly flammable

- Requires thorough post-processing to remove all residual solvents

- Stricter regulations due to safety concerns

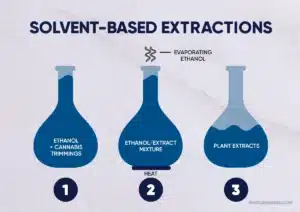

c) Ethanol Extraction

Ethanol extraction is another popular solvent-based cannabis extraction method that uses high-proof alcohol to dissolve cannabinoids and other compounds. It is one of the most cost-effective extraction processes, which typically involves:

- Cannabis plant material is soaked in ethanol, either at room temperature or chilled (to increase efficiency).

- Ethanol dissolves cannabinoids, terpenes, and other plant compounds.

- Then, the solution is passed through a filter.

- Ethanol is then filtered, and plant material is removed from the mixture.

- The remaining ethanol is evaporated, leaving behind the pure cannabis extract.

Advantages:

- Highly efficient extraction process for extracting a full spectrum of cannabinoids

- Ethanol is generally recognized as safe (GRAS) by the FDA

- Easier process as compared to hydrocarbon extraction

- Scalable for large-scale production

- Can target different compounds at various temperatures

Disadvantages:

- More prone to extract water-soluble compounds like chlorophyll, requiring additional purification

- Terpene preservation is not as effective as some other methods

- Requires large amounts of ethanol

d) Solvent Recovery & Winterization

A common challenge with any solvent-based extraction method is residue solvent. It may require adding steps to refine the final product.

- Solvent Recovery: Primary purification method, solvent recovery recaptures and purifies the solvent used in extraction. This process allows the extracted solvent to be reused, lowering the cost of operations, particularly when the solvent is expensive.

- Winterization: It is a post-extraction purification process that removes undesirable compounds like fats, waxes, and lipids from the extract. The process involves dissolving the extract in ethanol solution and then freezing the mixture. It solidifies waxes and fat, which are then filtered out. Ethanol is then evaporated, leaving behind a purer extract.

2. Solventless Extraction Methods

Solventless cannabis extraction methods rely on physical techniques rather than chemical solvents for extracting cannabinoids and terpenes. These techniques produce smaller yields than solvent-based methods, but they are often preferred for their purity and simplicity.

a) Rosin Press Extraction

The simplest solventless extraction method, rosin press extraction, uses pressure and heat to squeeze resinous sap from cannabis flower or hash.

The process is straightforward:

- Cannabis material is placed between two heated metal plates.

- Pressure is applied to the plates, resulting in oils to be expressed from the plant material.

- The resulting oil is collected and cooled to solidify.

Advantages:

- Results in highly pure and full-spectrum extract

- Simple process with minimal equipment required

- Preserves a full terpene profile

- Immediate results, no purging or post-processing needed

Disadvantages:

- Lower yields compared to solvent-based methods

- Can be time-consuming for larger batches

- Quality and yield are heavily dependent on the starting material

b) Ice Water Hash (Bubble Hash)

This method uses ice-cold water to separate trichomes from cannabis plant material. Here are the steps involved:

- Cannabis plant material is agitated in ice-cold water, causing trichomes to become brittle and break off.

- Water and trichome mixture is filtered through increasingly fine mesh bags.

- The collected trichomes are dried, resulting in hash.

Advantages:

- Chemical-free, clean, and natural product

- Excellent terpene retention for flavorful concentrates

- Extracts can be further refined into full-melt hash or rosin

Disadvantages:

- Process is labor-intensive

- Requires specific equipment (bubble bags)

- Lower yields compared to solvent-based extractions

c) Dry Sift Extraction

This process has been used for centuries to separate grains from plants. In dry sift extraction, fine screens are used to separate trichomes from the dried cannabis material physically. The process is simple:

- Dried cannabis plant material is gently agitated over fine mesh screens.

- Trichomes fall through the screens while more considerable plant material is retained.

- The collected trichomes form kief

- Kief is pressed into hash.

Advantages:

- A simple process requiring minimal equipment

- Produces a pure, potent product without any solvents

- This can be done at home with basic materials

Disadvantages:

- Yield is minimal

- Time-consuming for larger quantities

- This can lead to trichome wastage

Comparing Extraction Methods: Which One is Better?

Deciding which cannabis extraction method is the best depends on various factors, including the desired end product, production scale, and regulatory environment.

Let’s compare different scenarios and which method is better depending on the criteria:

1. Purity & Safety

CO₂ extraction method is a clear winner here as it produces the cleanest extracts, with no risk of residual solvents. In comparison, solventless cannabis extraction methods like rosin and ice water hash are also very pure but may contain plant waxes. Hydrocarbon and ethanol extractions have a risk for residual solvents.

2. Efficiency & Yield

Solvent-based methods, particularly hydrocarbon and CO₂ extractions, are commercially viable methods. These methods can process large batches of cannabis plants. The ethanol extraction method can be very efficient for CBD extraction, which is heat sensitive.

3. Flavor & Terpene Retention

Ethanol extraction is best for flavor and terpene retention. While hydrocarbon extraction is also excellent at preserving terpenes, it may lose some volatile compounds due to heat. Cold ethanol and CO₂ extractions can also preserve terpenes well if done carefully.

4. Scalability

Commercially, CO₂ and ethanol cannabis extractions have proven to be highly scalable. Hydrocarbon extraction methods can also be scaled up but may face regulatory hurdles due to safety concerns. Most solventless methods are generally less scalable, though industrial-scale rosin presses are becoming more common.

5. Consumer & Industry Preferences

Industry prefers methods that allow large-scale production of products at minimal operational costs, making solvent-based cannabis extraction methods their preference. However, consumers today prefer pure extracts that are produced without solvents.

Conclusion: Choosing the Right Extraction Method

Depending on the specific needs of the market you want to cater to and the available resources, the choice of cannabis extraction method can vary.

If you aim to produce medical-grade extracts, CO₂ extraction is the ideal method as it offers clean, consistent results and can isolate specific compounds. However, to serve recreational consumers, you need flavorful concentrates that can be produced with hydrocarbon extraction or rosin pressing. And, if large-scale CBD production from hemp is on your mind, ethanol extraction is often the most cost-effective option.

Each cannabis extraction method has advantages and disadvantages; the diversity of extraction techniques is the key to producing a wide range of products to meet varied consumer needs and preferences.