Before CBD can be transformed into the products we know and use, it must first be extracted from the cannabis plant. Among the various extraction methods available, CO2 extraction has emerged as a leading technique in the industry. So, what exactly is CO2 extraction, and why has it become the preferred method for extracting cannabidiol and other phytocannabinoids? In this guide, we will explore the essentials of CO2 extraction.

Sections

ToggleWhat is CO2 Extraction?

CO2 extraction is a sophisticated process of isolating specific compounds from plant materials. This method uses pressurized carbon dioxide gas as a solvent to extract desired elements from raw plant materials. The reason for using the CO2 extraction process is that it has minimal effect on the integrity of the extracts. Also, the process is known for its efficiency, safety, and ability to produce high-quality extracts. CO2 extraction is widespread in various industries, including food, cosmetics, and, most notably, in cannabis extraction.

What is CO2 Oil?

CO2 cannabis oil, popularly known as CO2 oil, is a concentrated extract produced through the CO2 extraction process. The term can refer to a full spectrum of cannabinoids, terpenes, and other beneficial compound oils obtained from the cannabis plant. CO2 oil, or CO2 cannabis oil, is known for its purity and potency. One of the reasons for the high demand for CO2 cannabis oil is the preservation of the plant’s natural chemical profile, which makes it more effective. CO2 oil is used in various products, from vape cartridges to edibles and topicals.

The Science Behind CO2 Extraction

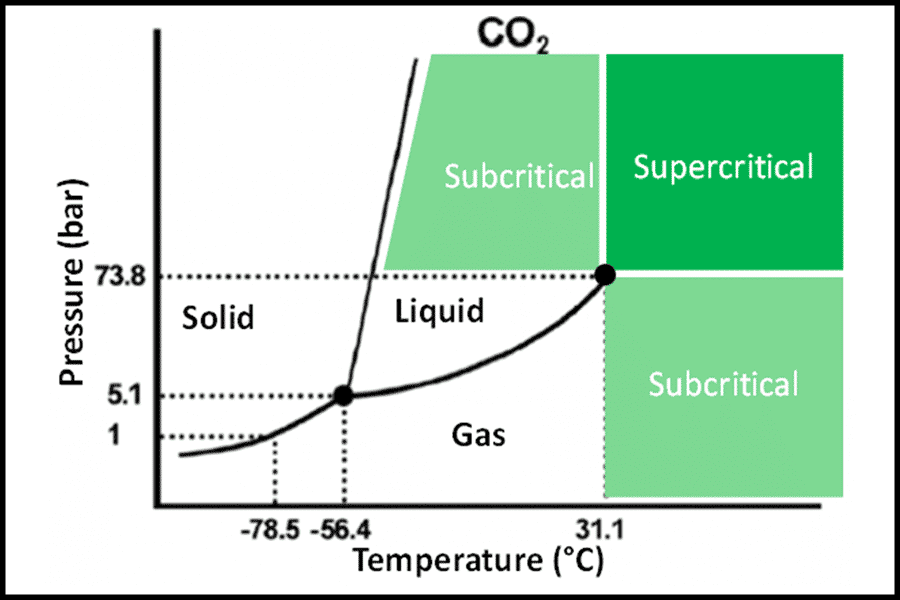

While CO2 cannabis extraction is a popular method, it is essential to understand the science behind the process. If you are considering installing a CO2 cannabis extraction machine, you must understand the infrastructural requirements. The CO2 extraction method is based on manipulating the state of carbon dioxide. In this process, the temperature and pressure of carbon dioxide gas are transformed into a “supercritical” state. In this state, CO2 exhibits the properties of both a liquid and a gas. The CO2 gas can efficiently penetrate plant material and dissolve targeted compounds at this stage.

In CO2 cannabis extraction, supercritical CO2 is a solvent for extracting compounds like cannabinoids and terpenes from the plant matter. As the process is highly selective, it allows the isolation of specific molecules, leaving behind unwanted substances. Due to its high efficiency, it is a preferred method in cannabis extraction.

Key Terminologies

There are some key terminologies producers handling CO2 cannabis extraction machines must know. Here are some of the common terminologies associated with CO2 extraction:

1. Supercritical CO2: It is the CO2 gas that has been heated and pressurized beyond its critical point. At this point, CO2 exhibits properties in both liquids and gases.

2. Subcritical CO2: For more delicate extraction, subcritical CO2 is used. It is the CO2 that is maintained below its critical point, exhibiting properties of a liquid and a gas at a lower temperature.

3. Fractionation: The process of separating different compounds based on their molecular weights.

4. Winterization: It is the post-extraction process used to remove unwanted waxes and lipids from the extract.

Types of CO2 Extraction - Subcritical, Midcritical & Supercritical

Depending on the state of the carbon dioxide, the CO2 extraction cannabis can be subcritical, midcritical, or supercritical. Let’s understand each process.

1. Subcritical CO2 Extraction

Subcritical CO2 cannabis extraction happens at lower temperatures and pressures. For subcritical CO2 extraction, the gas is pressurized up to 73.8 bar (7.38 MPa or 1,070 psi) at 31.1°C (87.98°F) or lower temperature. This gentler extraction process is ideal for extracting temperature-sensitive compounds.

In the subcritical CO2 cannabis extraction process, CO2 is kept below its critical point (31.1°C and 1,071 psi). This method is used when more volatile compounds must be extracted from the plant. The process is slower but more efficient for extracting terpenes and other delicate molecules without degrading them.

The cannabis extracted with this method is often more dense and contains a fuller spectrum of plant compounds. However, yields are typically lower compared to supercritical extraction.

2. Midcritical CO2 Extraction

Midcritical extraction operates in the range between subcritical and supercritical conditions. It balances the two methods: faster extraction and easier extraction of the more volatile extracts.

Midcritical CO2 cannabis extraction uses CO2 at temperatures > 31.1°C (87.98°F) and pressures < 73.8 bar (7.38 MPa or 1,070 psi).

This method offers broader applications than the subcritical method, extracting a more comprehensive range of compounds than subcritical extraction while being gentler than supercritical extraction. This extraction process helps create full-spectrum extracts and maintains a good balance of cannabinoids and terpenes.

3. Supercritical CO2 Extraction

The supercritical CO2 extraction method is the most commonly used process in the cannabis industry. It is used for its efficiency and versatility. This extraction happens at temperatures over 31.1°C (87.98°F) and pressures higher than 73.8 bar (7.38 MPa or 1,070 psi).

In supercritical CO2 cannabis extraction, gas is heated and pressurized beyond its critical point (typically 31.1°C and 1,071 psi). CO2 can diffuse through solids like a gas and dissolve materials like a liquid at its critical state. This makes the supercritical CO2 extraction highly effective at extracting various compounds from cannabis. This results in faster yields than subcritical methods.

How Does CO2 Extraction Work?

The process of CO2 extraction is simple, but the apparatus involved is sophisticated. Here’s a step-by-step guide to how the process works:

1. Preparation: The first step is to prepare the plant material for extraction by grounding and loading it into an extraction vessel.

2. Pressurization: CO2 is pumped into a chamber and pressurized to a supercritical state.

3. Extraction: In the extraction chamber, the supercritical CO2 is passed through the plant material to dissolve the desired compounds.

4. Separation: The CO2-extract mixture is then moved into a separator where pressure is reduced, causing CO2 to return to a gaseous state. It is then separated from the extract.

5. Collection: The extracted compounds are collected in a collector while the CO2 is recycled back into the system.

6. Post-processing: The raw extract may undergo further refinement in some processes, such as winterization or distillation.

Equipment and Technology Used

Modern commercial & industrial CO2 cannabis extraction machines are a complete setup of several components that are designed for precision and efficiency. Key components of a CO2 cannabis extraction machine include:

- Extraction vessel: To hold plant material and expose it to supercritical CO2.

- CO2 pump: To pressurize CO2 to the desired state.

- Heat exchangers: Control temperature throughout the system.

- Separators: Allow for the collection of extracted compounds.

- Recirculation system: Recycles CO2 for continuous use.

Root Sciences offers state-of-the-art CO2 extraction machines designed specifically for cannabis processing. The systems are based on the same legacy extraction method but improved by modern technology like automated controls, real-time monitoring, and modular designs for scalability.

Efficiency and Yield Factors

Several factors in the CO2 cannabis extraction process need to be micro-managed. The efficiency of the process depends on:

- Quality of raw plant material

- Extraction parameters such as temperature, pressure, and flow rate

- Equipment calibration and maintenance

- Post-extraction processing techniques

When properly optimized and quality equipment is used, like the one offered by Root Sciences, CO2 extraction can yield up to 95% of the available cannabinoids from plant material.

Pros and Cons of Each Type of CO2 Extraction

All three methods of CO2 extraction have their advantages and disadvantages. The choice depends on what is the intended product outcome. Here is what producers must know about the pros and cons of each extraction method:

| Type | Pros | Cons |

|---|---|---|

| Subcritical | Preserves heat-sensitive plant compounds Produces a more aromatic extract Gentler on the plant material | Lower cannabis yields Longer extraction times Less efficient for some cannabinoids |

| Midcritical | A more balanced extraction of wide spectrum of compounds Moderate yield and efficiency Good for full-spectrum extracts | Less selective than other methods More fine-tuning is required to midcritical temperatures and pressure |

| Supercritical | Highest yields of all extraction methods Faster extraction times Efficient extraction of a wide range of compounds | May degrade some terpenes Higher energy and pressure requirements More complex equipment needed |

Root Sciences CO2 extraction equipment helps you utilize all three extraction methods while offsetting the cons. Our equipment is designed to optimize the extraction process, save cost, and maximize yields.

Is CO2 Extraction Solventless?

CBD and Other Compounds Extracted During the CO2 Extraction Process

The CO2 cannabis extraction process is capable of isolating a wide range of compounds from cannabis and hemp plants. Producers can use this extraction process to offer a wide range of products.

Here’s a breakdown of the primary compounds extracted from the CO2 extraction process:

1. Cannabinoids

Several forms of cannabinoids can be extracted with this method. In the industry, the CO2 extraction process is used for the collection of the following:

CBD (Cannabidiol): It is the most sought-after non-psychoactive cannabinoid, primarily used for its potential therapeutic benefits.

THC (Tetrahydrocannabinol): Another core psychoactive compound in cannabis, it is used for oils and vapes.

CBN (Cannabinol): A mildly psychoactive cannabinoid formed from the degradation of THC, it is also used in the production of therapeutic end products.

CBG (Cannabigerol): A non-psychoactive cannabinoid often called the “mother of all cannabinoids.”

THCV (Tetrahydrocannabivarin): Another cannabinoid, it is used in diet supplements due to its potential appetite-suppressing properties.

2. Terpenes

In terpenes extraction, the CO2 extraction process offers much flexibility and ease. Here are some of the core terpenes extracted using this method:

- Myrcene: It is a terpene that is known for its earthy aroma and potential sedative effects.

- Limonene: It is known for its citrusy flavor and potential mood-enhancing properties.

- Pinene: A pine-scented terpene is therapeutic and has potential anti-inflammatory properties.

- Linalool: It is a floral terpene with potential calming effects in vapes and alternative medicines.

- β-Caryophyllene: Spicy terpene with potential anti-inflammatory properties.

3. Flavonoids

Flavonoids are another potential compound extracted from hemp and cannabis plants. These compounds are known for their antioxidant and anti-inflammatory properties. The two most widely produced flavonoids are Quercetin and Cannaflavin A.

4. Fatty Acids

In the food industry, the CO2 extraction method is widely used for extracting Omega-3 and Omega-6 fatty acids.

Apart from these compounds, some other ingredients are also extracted in the post-processing step of CO2 extraction. Chlorophyll, waxes, and lipids are typically removed during post-extraction processes like winterization.

Quality and Purity of Extracts with CO2 Extraction

CO2 extraction in the industry is known for its high-quality, pure extracts, particularly for CBD oil CO2 extraction and CO2 cannabis extraction. One of the main reasons for the high purity of the extracts is that, unlike other extraction methods, CO2 extraction leaves no residual solvents in the final product.

To better understand the quality and purity of extracts, let’s compare the extraction of Cardamom and Evening Primrose oil using the conventional methods and CO2 extraction:

Component | Conventional Extract | CO2 Extract | Difference |

Cardamom | |||

Terpinyl acetate | 40.44% | 50.0% | +9.56% |

1,8-cineole (Eucalyptol) | 29.90% | 25.40% | -4.50% |

Linalyl acetate | 5.02% | 6.30% | +1.28% |

Sabinene | 4.79% | 2.00% | -2.79% |

Linalool | 3.20% | 3.30% | +0.10% |

Limonene | 2.51% | 1.40% | -1.11% |

Myrcene | 1.96% | 0.41% | -1.55% |

Alpha terpineol | 1.79% | 2.20% | +0.41% |

Alpha pinene | 1.61% | 0.68% | -0.93% |

Geraniol | 1.11% | 0.72% | -0.39% |

Neral | 0.35% | 0.44% | +0.09% |

Geranial | 0.47% | 0.32% | -0.15% |

Evening Primrose | |||

Unsaponifiables | 1.7% | 3.5% | +1.8% |

Palmitic acid (C16:0) | 6.3% | 6.1% | -0.2% |

Stearic acid (C18:0) | 2.2% | 1.9% | -0.3% |

Oleic acid (C18:1) | 7.2% | 7.1% | -0.1% |

Linoleic acid (C18:2) | 73.3% | 74.5% | +1.2% |

Gamma Linolenic acid (C18:3) | 8.9% | 9.7% | +0.8% |

Sterols | 0.96% | 0.94% | -0.02% |

Tocopherols | 770 ppm | 300 ppm | -470 ppm |

Evidently, CO2 extraction helps preserve a plant’s natural flavor and aroma profile and maintains a higher concentration of beneficial compounds.

Advantages of Cannabis CO2 Extraction Method

Apart from the high purity of the extracts, there are some other benefits of this method, too:

1. Safety: CO2 extraction is non-flammable and non-toxic, making it much safer to work with as compared to methods using volatile solvents.

2. Versatility: The ability to micro-control the pressure and temperature of CO2 makes the process highly versatile. It makes it possible to produce a wide range of extracts, from CO2 hash oil to CBD oil CO2 extraction.

3. Efficiency: CO2 extraction can achieve high yields, especially when optimized for specific compounds.

4. Product quality: Compared to traditional methods, CO2 extraction produces clean, high-quality extracts with no residual solvents.

5. Terpene preservation: Lower processing temperatures help maintain the plant’s natural terpene profile.

Environmental and Cost Benefits

1. In this method, CO2 used in the process can be recycled, reducing waste and environmental impact.

2. While the initial setup costs of CO2 extraction equipment can be high, it is more energy-efficient in the long run than other extraction methods.

3. The clean nature of CO2 extracts often requires less post-processing, saving time and resources.

4. Due to the modularity of the CO2 extraction machines, production can be scaled up efficiently to meet increasing demand.

CO2 Extraction vs. Conventional Methods Comparison

When we compare the CO2 extraction process with conventional methods, particularly solvent-based extractions like ethanol and hydrocarbon extraction, there are both pros and cons:

CO2 Extraction

Pros:

- Clean, solvent-free extracts

- Highly customizable process

- CO2 is safe and non-flammable

- Method preserves terpenes and original chemical profile

- Sustainable and environmentally friendly

Cons:

- High initial equipment cost

- Requires more technical expertise to operate

- Longer extraction times compared to some methods

Hydrocarbon Extraction

Pros:

- This method is faster than CO2 extraction.

- High yields for certain compounds, such as cannabis oil

- Lower initial equipment cost

- Effective for extracting non-polar compounds

Cons:

- Hydrocarbons are highly inflammable

- Potential for residual solvents

- Stricter regulations and facility requirements

Check out our more detailed guide on Co2 vs BHO extraction.

Ethanol Extraction

Pros:

- Relatively simple and fast process

- Effective for full-spectrum extracts

- Lower equipment costs compared to CO2

- Generally recognized as safe (GRAS) by FDA

Check out comprehensive guide on Ethanol vs Co2 extraction.

Cons:

- Extracts can have high residual solvent

- May extract unwanted compounds like chlorophyll

- Less selective than CO2 extraction

Uses of CO2 Extracts

The CO2 extraction method has applications across industries. Depending on the nature of the ingredients and the budget available, the CO2 extraction method can be used for several reasons.

Cannabis Industry Applications

One of the most widely used methods in the industry, CO2 extraction is used for:

- CO2 cannabis oil production for vape cartridges and edibles

- It is preferred for producing high-potency CO2 hash oil and CO2 wax

- Preferred for terpene extraction for flavor and aroma enhancement

- CBD oil extraction of the finest quality

- Manufacturing of CO2-infused joints for enhanced potency

Apart from the Cannabis industry, there are other applications of the CO2 extraction process.

- In the food and beverages industry, this method is used for the extraction of flavors, colors, and nutritional compounds

- The cosmetics industry relies on the CO2 extraction process for the production of natural fragrances and active ingredients

- In pharmaceuticals, the method is used for the extraction of medicinal compounds from plants

- Nutraceuticals also depend on CO2 extraction method for producing health supplements and functional foods

Apart from the current applications, the CO2 extraction method also has future potential, with innovations taking place in equipment. Nanoemulsions, the development of water-soluble cannabis extracts, is one application that holds promise for products that have improved bioavailability. Also, CO2 extraction can be used for industrial hemp processing with the right equipment and is beneficial for large-scale CBD extraction for various applications.

CO2 Extraction Equipment Prices

Initial investment in CO2 extraction equipment can be significant, with high-end systems costing upwards of $150,000 to $500,000. This can discourage some producers, but a cost vs. benefits analysis is essential to making the final decision.

If you are a US based business, Rootsciences can offer upto $10 million in equipment financing

While the initial setup cost may be high, the long-term benefits of CO2 extraction outweigh the initial costs. The higher quality of extracts earns premium prices in the market and results in higher revenue from the same resources. There is also a significant cost reduction in post-processing due to cleaner initial extracts. Once the setup runs, the operational costs are lower than those of other methods because CO2 is recycled into the system. The versatility of the process allows for the production of various high-value products.

Scaling up operations with the CO2 extraction method is comparatively easier. For instance, a CO2 extraction machine by Root Sciences can be expanded to increase its capacity. Also, you need to consider automating processes to increase efficiency and developing standardized operating procedures to smooth scale production.

How To Choose A CO2 Extraction Equipment?

A CO2 extraction machine is a sophisticated system with several components working together to precisely control temperature, pressure, and flow rates during extraction. These machines typically consist of a CO2 tank, pump, extraction vessel, separator, and collection chambers.

When choosing a CO2 extraction machine, producers must consider the capacity based on not only present demand but near future production needs. Choose machines with a high level of automated controls for the consistency of end products. Ensure the system can achieve the desired extraction pressure and temperature parameters. Also, it must have safety features like automated shut-offs and pressure release valves.

Also, maintenance and operational requirements of the equipment, such as regular cleaning and sanitization of all components, must be considered. Ensure periodic replacement of seals, filters, and other worn items. Invest in proper training for operators to ensure safe and efficient operation.

Safety Considerations

While CO2 is generally considered safe and non-toxic, the high pressures involved in the process necessitate strict safety protocols. To ensure safety in CO2 cannabis extraction, proper training, regular equipment maintenance, and adherence to safety guidelines are essential.

Regulations and Compliance in CO2 Extraction

CO2 extraction is also subject to regulatory and compliance requirements like other industrial activities. You must ensure that the process, equipment, and production activities comply with the state and local cannabis regulations. Obtain necessary licenses and permits for extraction operations. Also, adhere to zoning requirements for extraction facilities while ensuring compliance with OSHA safety standards for high-pressure equipment.

Most trusted producers meet industry standards such as Good Manufacturing Practices (GMP) certification, ISO 9001 quality management system implementation, and compliance with FDA regulations for food-grade extracts.

Overcoming Challenges in CO2 Extraction

Common challenges faced during the CO2 extraction process include pressure fluctuations, CO2 purity, and equipment maintenance. As supercritical CO2 can be complicated to handle, equipment needs regular maintenance to ensure the safety and integrity of the process.

To overcome these challenges:

- Implement robust quality control measures such as regular testing of raw materials and final products.

- Maintain detailed records of extraction parameters for each batch to ensure consistency in product quality.

- Invest in staff training to ensure consistent equipment operation.

- Engage consulting services for expert assessments of your CO2 extraction process, ensuring optimal equipment performance and compliance with industry standards, while addressing potential issues early.

Conclusion

CO2 cannabis extraction is playing an increasingly important role in the cannabis industry. Its ability to produce clean, potent, and diverse extracts makes it an invaluable tool for producers. Industry depends on this extraction process to create high-quality cannabis products. As the industry matures and consumers become more discerning, advanced extraction methods like CO2 extraction for producing potent and pure products are more likely to grow in demand.

Root Sciences offers advanced CO2 cannabis extraction machines incorporating modern technology to optimize extraction parameters in real-time, improving efficiency and consistency. Our equipment features a fully automated control system, 100% communication with ancillary equipment, sub & supercritical extraction capabilities, and more.