With increasing interest in natural products, consumers prefer extracts sourced naturally. Cold-pressed extraction is a buzzword, but CO2 extraction remains a commercial success. This challenges manufacturers with the dilemma of cold-pressed vs CO2 extraction.

Both techniques offer their advantages, serving different purposes across industries. This article explores the differences between these extraction methods, including their applications and the most effective methods for various scenarios.

Sections

ToggleWhat is CO2 Extraction?

The CO2 extraction method uses supercritical carbon dioxide to extract desired compounds from the plant material. The process utilizes specialized equipment to maintain CO2 in a critical state at 31.1°C (or 87.8°F) and 7.38 MPa (or 73.8 bar) pressure. The process is known for its high purity and efficiency in extraction.

How It Works:

- Supercritical CO₂ Formation: The first step of the process is to pressurize carbon dioxide and heat until it reaches a supercritical state, combining liquid and gas properties.

- Extraction Process: The supercritical CO2 is introduced in a plant-material chamber. It acts as a solvent, penetrating the plant material and dissolving compounds like terpenes and cannabinoids.

- Separation and Collection: The mixture of CO2 and compounds is put in the collection chamber. Here, pressure is reduced, causing CO2 to return to gas form and leaving behind pure extracted compounds.

Common Uses of CO2 Extraction-

While this extraction process is used across industries, here are the most widely found applications:

- CBD and Hemp Extracts: In the cannabis industry, CO2 extraction is used for producing high-purity cannabinoids and terpenes for medical and recreational use.

- Essential Oils: It also produces pure, concentrated oils for aromatherapy and personal care products without residual solvents.

- Pharmaceuticals: Due to its high purity and efficiency, this process extracts active compounds for medication and supplement production.

What is Cold-Pressed Extraction?

A method used for centuries, cold-pressed extraction is a fully mechanical process that uses pressure to extract oils and compounds from raw materials. This method doesn’t use heat, which is appropriate for preserving volatile terpenes and compounds.

How It Works:

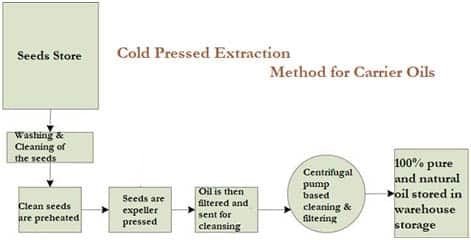

- Raw Material Preparation: Before pressing, plant material is cleaned and sometimes crushed or ground to increase surface area for extraction.

- Mechanical Pressing: Heavy pressure squeezes oils and compounds from the raw material using a mechanical press.

- Filtration & Collection: Extracted oil is filtered to remove solid particles and collected for use.

Common Uses of Cold-Pressed Extraction:

- Plant-Based Oils: Due to its lack of heat, cold-pressed extraction is highly effective for producing natural oils from nuts, seeds, and fruits for cooking and dietary use.

- Juices & Beverages: It is a standard process for extracting fresh, nutrient-rich juices from fruits and vegetables.

- Skincare & Cosmetics: Cold-pressed natural oils are preferred for beauty and personal care products.

CO₂ Extraction vs. Cold-Pressed Extraction: Key Differences

Aspect | CO₂ Extraction | Cold-Pressed Extraction |

Process | Complex, technology-driven process requiring specialized equipment | Simple, mechanical process can be done with simple tools |

Temperature | Needs to maintain low temperature (31.1°C) | Needs room temperature |

Solvent Use | Uses CO₂ (non-toxic) | No solvents |

Purity | Very high and can be even more refined | High but not as high as CO2 extraction |

Yield Efficiency | Very High (90-95%) | Moderate (65-75%) |

Applications | Used widely for specialized compounds across industries | Mostly used for general oils and juices |

Cost & Equipment | High investment | Lower investment |

Sustainability | Moderate due to high energy requirement | Highly sustainable process without any energy use |

Advantages of CO₂ Extraction

To make an informed choice, you have to understand the applications of each in this cold-pressed vs CO2 extraction comparison. Let’s start with the CO2 extraction method first.

- High Purity: The CO2 extraction produces exceptionally pure extracts with minimal contamination. Also, the process can selectively target specific compounds. This makes this process ideal for pharmaceutical and medical applications.

- Precise Control: Due to specialized equipment, the method offers precise control over pressure, temperature, and flow rate. It makes customizing extraction parameters based on the target compound easy.

- Solvent-Free: Since CO₂ completely dissipates after extraction, there is no solvent residue in the final product. It ensures a clean and safe extract for medical and recreational use.

- Longer Shelf Life: Extracts produced with the CO2 extraction method have extended shelf life due to the absence of oxygen during processing. By preventing oxidation, it slows down degradation.

Advantages of Cold-Pressed Extraction

Popular among producers emphasizing sustainable and natural products, cold-pressed extraction offers:

- Nutrient Retention: Cold pressing is a heat-free mechanical process that preserves heat-sensitive nutrients, enzymes, and compounds. It avoids degrading caused by other extraction methods, resulting in more nutritionally complete products.

- Completely Chemical-Free: The process uses no chemicals or solvents. It is ideal for organic and natural product certification and appeals to health-conscious consumers.

- Eco-Friendly: Cold pressing saves energy as it requires minimal energy and produces no chemical waste. It is one of the most environmentally sustainable extraction methods available.

- Cost-Effective: Lower equipment costs and minimal operating expenses make cold pressing highly cost-effective and suitable for small to medium-scale production.

Which Extraction Method is the most effective?

At this point, you are aware of the CO2 extraction vs cold-pressed comparison points and advantages. However, there is no one winner, and the choice of the most effective extraction method depends mainly on the intended application and desired outcome.

If you are targeting high purity, precise compound isolation, and pharmaceutical-grade products, CO₂ extraction is superior. On the other hand, cold-pressed extraction is best for producing natural, nutrient-rich oils and juices where maintaining the original nutritional profile is crucial.

The CO2 extraction method effectively extracts sensitive compounds like cannabinoids and essential oils, prioritizing purity and consistency. Cold-pressed extraction can be preferred for food-grade oils, natural cosmetics, and products with minimal processing.

Conclusion

No method is superior to another when comparing cold pressed vs CO2 extraction. Each extraction method serves distinct purposes and offers unique advantages. CO2 extraction is a technologically sophisticated method offering precise compound isolation. Cold pressing is excellent for natural preservation and environmental sustainability. Consider factors such as target compound, desired purity, scale of production, and intended use when making the choice. This understanding helps manufacturers select the most appropriate method for their needs.