In the extraction industry, CO2 extraction is one of the leading methods for creating high-quality botanical concentrates. From cannabis extraction to food processing, CO2 extraction has applications across sectors. However, the extracts obtained by this method (known as CO2 oil) can contain plant waxes, lipids, and other undesirable compounds. It can affect the quality and usability of these extracts, which is why dewaxing CO2 oil is essential.

This guide explores the dewaxing process involved in producing premium-grade extracts, dewaxing CO2 oil techniques, and benefits.

Sections

ToggleWhat is the Dewaxing Process?

Dewaxing is a refined method for removing naturally occurring plant waxes, lipids, and other high-molecular-weight compounds from extracts. There are mainly two CO2 oil dewaxing techniques used for creating cleaner, more refined products:

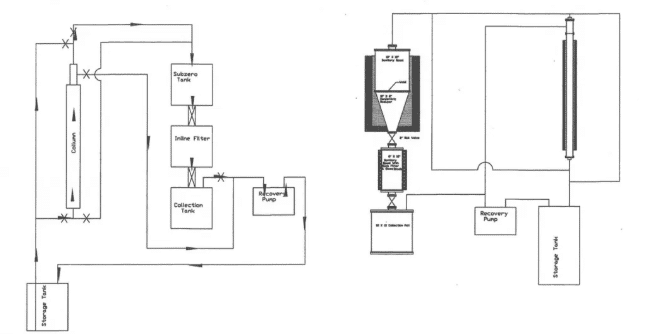

- Inline Dewaxing: When dewaxing is performed during the initial CO2 extraction by manipulating temperature and pressure parameters, it is known as inline dewaxing.

- Winterization: This dewaxing technique is used post-extraction. It uses cold temperatures and solvents to separate and remove waxes from the CO2 oil.

Why Dewaxing CO2 Oil is Important?

There are several reasons why dewaxing CO2 oil becomes a necessity:

- Improves clarity and color: Waxes are opaque in appearance, and removing them from extracts makes them clear and improves color, creating a more translucent extract.

- Enhances Smoothness: Dewaxed oils have smoother fluidity, and users experience less harshness when vaporizing or consuming them.

- Prevents Clogging: Wax-free CO2 oil extracts prevent clogging in vaporizers, cartridges, and other delivery devices.

- Boosts Potency: Waxes and lipids dilute the potency of extract and by removing these non-active compounds, the relative concentration of desired compounds is increased.

- Ensures Compliance: Some jurisdictions have quality standards requiring lower wax content for specific product categories.

When Should Dewaxing Be Performed?

Depending on your technique, dewaxing can be performed during or after CO2 extraction.

1. Inline Dewaxing

Performed during the CO2 extraction, inline dewaxing uses carefully controlled temperature and pressure to minimize wax extraction at the source.

Pros:

- Significantly reduces post-processing time and resources

- Minimizes product loss due to post-processing

Cons:

- Requires more sophisticated equipment for precise controls

- Can cause more than usual quantity of desirable compounds to be left behind

2. Winterization

After the initial CO2 extraction process, winterization is performed by dissolving the extract in ethanol and freezing it to precipitate waxes for filtration.

Pros:

- More thorough removal of waxes and lipids

- More efficient and results in less wastage of desired compounds

Cons:

- Requires additional solvents and processing time

- This can result in the loss of some temperature-sensitive terpene

Step-by-Step: How to Dewax CO₂ Oil

1. Prepare the Extract

The first step is dissolving raw CO2 extract in food-grade ethanol in a 10:1 ratio (ethanol to extract). Prepare a homogeneous solution by thoroughly mixing for effective wax separation during freezing.

2. Freeze the Mixture (Winterization)

Cool the ethanol-extract solution at temperatures between -20°C and -30°C for 24-48 hours. The waxes and lipids solidify at this temperature and precipitate out of the solution.

3. Filter Out Waxes

Filter the wax from ethanol-extract solution using vacuum filtration with a Buchner funnel and appropriate filter papers (typically 1-5 microns). Ensure the temperature is cold throughout the filtration process to prevent waxes from redissolving.

4. Remove Ethanol

In the final step, use a rotary evaporator or vacuum oven to remove the ethanol from the filtered solution safely. Typically, the temperature should be below 40°C to preserve heat-sensitive compounds at this stage.

Best Practices and Pro Tips

- Use food- or lab-grade ethanol: As such, ethanol has the highest purity levels, and no impurities can contaminate your final product and compromise quality.

- Keep consistent cold temperatures: Ensure the whole setup is maintained at a constant temperature during freezing or filtration. This ensures waxes do not redissolve.

- Don’t rush filtration—patience = purity: Dewaxing CO2 oil is a gradual process based on slower filtration. This yields cleaner results, as rushing the process can force waxes through filters.

- Regularly clean equipment: Any residual wax buildup on equipment surfaces can cause contamination of future batches and reduce efficiency.

Common Mistakes to Avoid

- Inadequate freezing time: Any temperature fluctuations during the winterization process can cause waxes not to precipitate or redissolve fully, resulting in products that still contain wax content.

- Improper filtration: Not using appropriate filters or applying too much pressure during filtration can allow waxes to pass through.

- Not removing ethanol entirely: Any residual solvent must be removed from extracts as it affects flavor and creates safety issues.

- Incorrect storage afterward: Just creating high-quality oil is not enough; properly storing dewaxed CO2 oil is essential to avoid crystallization.

Impact of Dewaxing on Final Product

- Appearance

Dewaxed CO2 extracts are clearer and have more bright colors. Dewaxing avoids extracts that have an opaque, darker appearance, indicating higher quality.

- Performance

Removal of waxes and lipids makes the extract more potent and reacts fast with heat, improving its vaping performance. Also, removing wax reduces residue buildup in devices.

- Flavor

Waxes and lipids add an unpleasant and harsh taste; dewaxing enhances the desirable flavor compounds and terpene profiles, resulting in a more authentic taste experience.

- Shelf Life

Dewaxing CO2 oil extends its shelf life and stability by removing compounds that can degrade over time.

Conclusion

Dewaxing is a crucial refinement technique to create premium-grade CO2 extracts. Dewaxed CO2 extracts have superior clarity, potency, and performance characteristics, significantly improving the quality and marketability of the extracts.