The cannabis market is evolving; consumers expect more innovative products offering better experiences. To meet this growing demand for purity, consistency, and potency in the cannabis industry, producers utilize advanced techniques. One such method is fractional distillation of cannabinoids, which allows producers to isolate and purify compounds with specific cannabinoid profiles.

Here, we explore the fractional distillation process of producing premium cannabis extracts and therapeutic formulations.

Sections

ToggleWhat is Fractional Distillation?

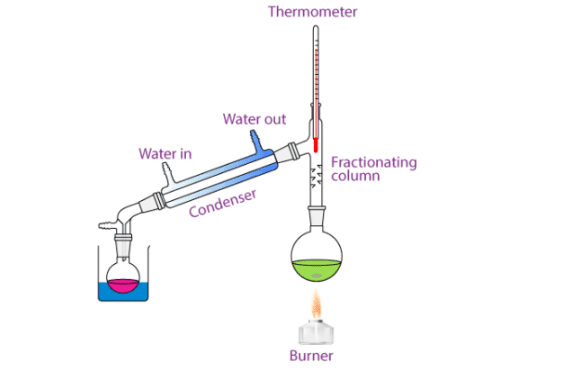

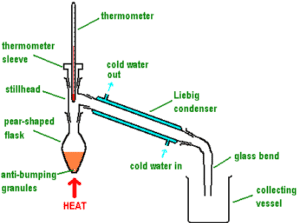

Fractional distillation of cannabinoids is a separation technique that utilizes different boiling points of various compounds to isolate them with exceptional purity. Unlike simple distillation, this process uses a fractionating column to separate molecules with boiling points differing by just a few degrees.

In cannabis processing, fractional distillation allows precise separation of cannabinoids like THC, CBD, and minor cannabinoids at more than 95% purity.

Setup and Step-by-Step Process of Fractional Distillation in Cannabis

For fractional distillation of cannabis, proper setup is necessary. Specialized equipment is required for precise temperature control and careful monitoring throughout the operation to achieve optimal results.

A. Equipment Setup

- Heating mantle – provides controlled, even heat distribution to the boiling flask

- Boiling flask – contains the crude cannabis extract

- Fractionating column – a core component of the system it allows vapors to condense and re-vaporize multiple times, enhancing separation

- Thermocouples/Temperature sensors – monitor and control temperature throughout the system for precision

- Condenser – cools purified cannabinoid vapors back into liquid form

- Receiving flasks – collection vessels to collect different cannabinoid fractions

- Vacuum pump – creates reduced pressure in the system, lowering boiling points

- Cold trap – protects vacuum pumps by condensing any vapors entering the vacuum pump

B. Step-by-Step Process

- Prepare crude oil – Cannabis extract is prepared for extraction by winterization or decarboxylation. These preliminary filtrations remove waxes, lipids, and chlorophyll.

- Load the boiling flask – Prepared crude extract is loaded into the boiling flask, which is then securely connected to the fractionating column.

- Apply head and vacuum – The vacuum pump maintains pressure typically between 0.01-1 mbar to lower boiling points. Heat is gradually applied to the flask.

- Fractionation begins – With the temperature rise, different compounds vaporize sequentially based on their boiling points.

- Condensation and collection – Purified vapors pass through the condenser and return to liquid form. Purified extract liquids are collected in the receiving flasks.

- Re-run for higher purity – For ultra-pure isolates, the collected cannabis fractions undergo a second or even third distillation cycle. Repeated fractional distillation of cannabinoids can achieve purities exceeding 99%.

Why Fractional Distillation Matters in Cannabis

- High Purity – As mentioned, fractional distillation cannabis can have purity as high as 99%; the process becomes essential for reliable pharmaceutical and medical applications.

- Consistent Dosing – Precisely isolated cannabinoids allow manufacturers to create products with exact potency specifications.

- Contaminant Removal – Fractional distillation can eliminate contaminants like pesticides, heavy metals, and residual solvents.

- Customizable Output – By controlling temperature, producers can create custom cannabinoid blends with specific ratios.

- Compliance-Ready – High purity makes fractional distillation of cannabinoids ideal for creating products that meet stringent regulatory requirements.

Benefits of Fractional Distillation

- Superior Purity – The purity of cannabinoids produced by fractional distillation is superior to any other extraction method. It allows producers to achieve pharmaceutical-grade purity levels.

- Targeted Cannabinoid Extraction – Precise temperature control allows the selective collection of specific cannabinoids. Such selectivity enables the isolation of even rare cannabinoids.

- Cleaner Taste & Aroma – By purifying extract of plant lipids, waxes, chlorophyll, and other non-target compounds, fractional distillation of cannabinoids produces cleaner, more neutral products.

- Versatile Applications – Distillate cannabis extracts can be incorporated into any delivery system. As they are odorless, tasteless, and highly concentrated isolates, they are ideal for almost every application, from precision-dosed pharmaceuticals to consumer products.

- Stability – Fractional distillation removes reactive compounds and impurities from cannabinoids, significantly extending their shelf life.

Common Challenges and Considerations

- High Equipment Costs – Commercial fractional distillation of cannabinoid systems is expensive specialized equipment. Initial investment for industrial-scale equipment can range from $50,000 to several hundred thousand dollars.

- Technical Skill Required – To operate these systems, skilled workers with knowledge of cannabis chemistry and distillation techniques are required.

- Thermal Sensitivity – Volatile compounds in cannabinoids can degrade in case of heat exposure, even with vacuum assistance lowering boiling points. That’s why fractional distillation of cannabis must carefully balance separation efficiency against thermal exposure.

- Time-Consuming – Fractional distillation is not a rapid process and typically takes several hours to complete a single run. Also, additional time is required for system preparation and cleaning.

Applications of Fractionally Distilled Cannabis Products

- Vape Oils – The high purity and viscosity of cannabinoid distillates make them ideal for vaping, providing consistent potency.

- Tinctures and Capsules – Precise cannabinoid content is excellent for therapeutic products.

- Edibles – The neutral flavor profile of such extracts makes them suitable for food products without a strong herbal taste.

- Topicals – Clean distillates absorb effectively through the skin, making them ideal for topical formulation for localized application.

- Pharma-Grade Products – One of the most significant applications of fractional distillation cannabis is in the pharmaceutical industry, clinical research, and regulated medical cannabis programs.

Fractional Distillation vs. Other Purification Methods

Method | Purpose | Purity | Common Use |

Fractional Distillation | Separation of cannabinoids by exploiting differences in their boiling points | 95-99% | Pharmaceutical products, vape cartridges, precision-dosed formulations |

Winterization | For removal of waxes, lipids, and fats from cannabis extracts | 70-85% | Pre-processing of cannabis oils for basic refinement |

Simple Distillation | Basic separation of volatile components | 75-90% | Less refined oils, intermediate processing stage |

Chromatography | Isolation of specific cannabinoids using molecular characteristics | 99%+ | Research, pharmaceutical development, isolation of rare cannabinoids |

Conclusion

Fractional distillation of cannabinoids is a transformative technique bridging the gap between traditional botanical extraction and pharmaceutical-grade production. Producers can offer unparalleled purity, consistency, and customizability as a sophisticated purification method.

You can use fractional distillation cannabis products to distinguish your brand in a competitive market. While the equipment costs and technical requirements may be challenging, the value-added benefits make fractional distillation a reliable method for commercial success and scientific advancement.