Short path distillation gets its name because the distillate vapor has to travel a very short distance in this process. It is a highly efficient separation technique used widely in the cannabis industry to produce high-quality extracts and compounds. In this comprehensive guide, we’ll discuss short path distillation for producers. We will cover its fundamental principles and practical applications to share valuable insights into the short path distillation process and equip you with the knowledge to set up and operate your equipment.

Sections

ToggleUnderstanding Short Path Distillation

Short path distillation is a specialized form of distillation usually used for separating and purifying substances with low boiling points. This method is used in the cannabis industry because it is suitable for high-purity products, such as in the production of essential oils, pharmaceuticals, and specialty chemicals.

The fundamental principle behind short path distillation lies in its unique apparatus design. It minimizes the distance between the heating element and the condenser. This short path from vapor formation to distillate collection offers several advantages:

- Reduced thermal degradation: Utilizing low temperatures helps preserve the integrity of heat-sensitive compounds.

- Enhanced efficiency: The short distance allows for quick vaporization and condensation, improving the overall efficiency of the process.

- Higher purity: The reduced path length can significantly minimize the chance of unwanted reactions or contamination during the distillation process.

The short path distillation works on the principle of differential vaporization. Substances with lower boiling points vaporize first; using the equipment, they are quickly condensed and collected in pure form, while higher boiling point components remain in the distillation flask.

How Short Path Distillation Works

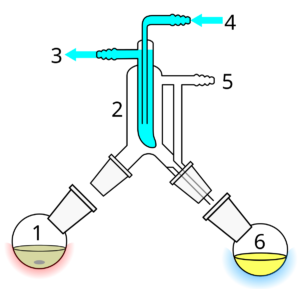

Let’s detail how short path distillation works, breaking down the entire process into individual steps and how each step contributes to the whole process:

- Heating: The source mixture of cannabis to be distilled is placed inside a boiling flask. The mixture is heated to its boiling point using a heating mantle or similar device with precise temperature control.

- Vaporization: As the temperature rises, the cannabis components with lower boiling points vaporize, first rising and entering the condenser tube.

- Condensation: The vaporized molecules quickly travel to the cooled condenser tube. In the condenser, the vapor is rapidly condensed back into liquid form.

- Collection: The condensed liquid flows down the condenser and is collected in a receiving flask in the purest form. There can be more than one collection of flasks in a more sophisticated short path distillation equipment.

- Vacuum application: A vacuum pump can be used to lower the boiling points of the compounds. Distillation can be carried out at lower temperatures by lowering the boiling point to protect heat-sensitive materials further.

The process is simple but requires precise temperature control for heating and condensation. The efficiency of short path distillation lies in its ability to perform these steps rapidly and with minimal material loss.

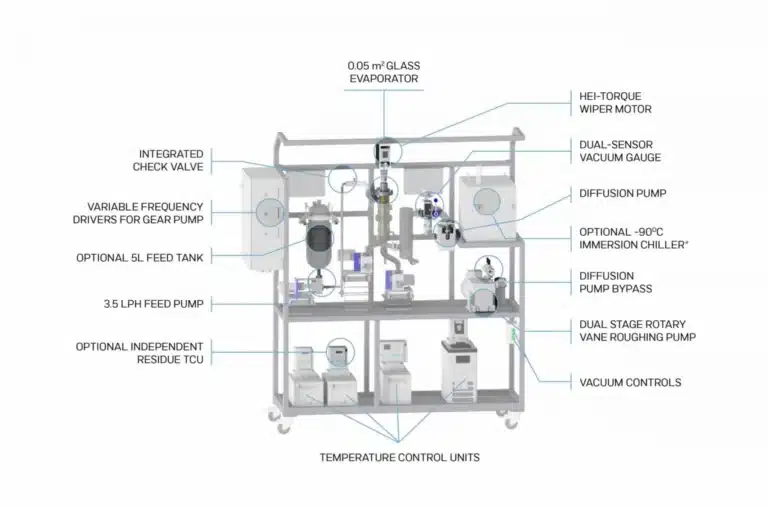

Components of a Short Path Distillation Setup

A typical short path distillation setup consists of several essential components. Here are the most crucial elements that facilitate the distillation process:

- Heating Mantle: Most distillation equipment has heating mantles that provide controlled and even heating to the boiling flask.

- Boiling Flask: Heat resistance boiling flasks contain the mixture to be distilled. The boiling flask has a round bottom for even heat distribution.

- Distillation Head: A specially designed cork-like head connects the boiling flask to the condenser. It also includes a thermometer port for temperature monitoring.

- Condenser: A cooled chamber condenses vapors back into liquid form. Typically, short path distillation equipment has a cold finger condenser.

- Receiving Flasks: This flask with a flat base collects the distilled fractions as they condense.

- Vacuum Pump: It is used to suck the air out of the boiling flask to create reduced pressure in the system, lowering boiling points and enhancing separation.

- Thermometer: For precise temperature monitoring, the thermometer is used for both boiling and condensation temperature control.

- Vacuum Gauge: Measures and helps maintain the desired vacuum level.

Enthusiasts and producers should understand the function of each component is essential. Generally, a short path distillation kit has all these components that provide high efficiency and precision.

Master Short Path Distillation with Confidence

Short Path Distillation Setup: A Step-by-Step Guide

Setting up short path distillation equipment requires understanding the apparatus, attention to detail, and a systematic approach. While the accurate steps of setup will depend on the kind of short path distillation kit you have, here are the common steps to ensure a proper setup:

1. Position the heating mantle on a stable surface, ensuring it’s level and secure. You must also grease all the equipment connections to provide a vacuum seal.

2. Attach the boiling flask to the heating mantle, ensuring it’s seated properly. Connect the distillation head to the boiling flask, providing a tight seal. Attach the condenser to the distillation head, aligning it properly to ensure the distillate drops fall into the receiving flasks. Secure the receiving flask to the condenser outlet firmly.

3. The next step is to attach the vacuum pump to the system and turn on the pump; if all the connections are leak-proof, the gauge should show <50 millitorr (microns) in 5-10 minutes.

4. Connect the cooling system to the condenser and align it properly to ensure the proper flow of distillate. Typically, a temperature between 0 to 25 degrees is adequate for distillate cooling, but you should ensure it doesn’t drop below 0 as it can degrade the quality.

5. Double-check all connections and seals before starting the distillation process. The boiling temperature you need to maintain will depend on the cannabinoid extracts you want to distillate.

Common setup mistakes to avoid:

- Use a thermometer for precise temperature control of the equipment

- Make sure the build material of the short path distillation kit is non-reactive so it doesn’t contaminate the distillate

- Neglecting to grease ground glass joints properly can compromise the integrity of the system

- Overlooking small leaks in the vacuum system

By following these steps and avoiding common mistakes, you can easily ensure that the short path distillation setup is ready for optimal performance.

Types of Short Path Distillation Units: Benchtop vs. Wiped/Thin Film Distillation Systems

Short path distillation equipment comes in various forms, with benchtop units and wiped/thin film systems being the most common.

Usually, lab distillation equipment is a benchtop design that is highly flexible and easy to use. They have no moving components and need less calibration. On the other hand, wiped/thin film systems are industrial-scale short path distillation units with a rotating wiper blade that ensures proper heat transfer in the source material and minimizes residence time.

Here’s a comparison of these two types:

Aspect | Benchtop Short Path Distillation | Wiped/Thin Film Distillation Systems |

Scale | Small to medium | Medium to large |

Throughput | Lower end product | Higher produce |

Heat Sensitivity | Excellent for heat-sensitive materials with precise temperature control | Good, but may expose cannabis material to more heat |

Operational Complexity | Simpler to operate | More complex, requires more expertise for handling industrial grade equipment |

Cost | Generally lower | Higher initial investment |

Flexibility | More versatile for various applications | Specialized for high-volume production for a limited extracts |

Residence Time | Longer residence time | Very short residence time |

Maintenance | Easier to clean and maintain | More complex maintenance requirements |

Pros and Cons of Popular Fractionation Methods

Short path distillation is a fractionation method. It is preferred in the industry because it stands out for its ability to efficiently handle heat-sensitive materials and produce high-purity distillates.

Let’s explore the pros and cons of each fractionation method.

Method | Pros | Cons |

Short Path Distillation | High purity of distillates Low operating temperatures Suitable for heat-sensitive materials Efficient for small to medium scales | Limited throughput for large-scale operations Higher initial equipment cost Requires vacuum system |

Thin Film Distillation | High throughput Continuous operation ensuring high production Efficient for large-scale production | Higher operating temperatures More complex setup requiring skilled staff Less suitable for small batches as the process can be expensive |

Fractional Distillation | Most widely used method across industries Suitable for a wide range of materials Can be scaled up | Less efficient for heat-sensitive materials Requires longer processing times May require multiple passes for high purity |

Design Considerations for Short Path Distillation Units

Whether you are an aspiring distillate producer or an industrial producer, while choosing a short path distillation kit, consider these factors:

- Choose a high-quality vacuum system that can effectively lower the system’s temperature. It is crucial for maintaining low pressures and ensuring efficient distillation.

- Temperature control systems with advanced electronics are essential for achieving optimal separation and avoiding thermal degradation.

- Short path distillation equipment must be inert such that all components in contact with the distillate must not contaminate the distillate.

- The design of the condenser should be high quality to ensure the overall efficiency of the distillation process.

- Any short path distillation unit should be scalable. Consider future needs and choose a system that can be scaled up if necessary.

- As distillation equipment requires continuous maintenance, look for designs that allow easy disassembly and cleaning.

Customization and modifications can further enhance the performance of the equipment. Choose designs that can add multiple receiving flasks for fractional collection. Implementing digital temperature and pressure monitoring systems can further improve efficiency.

Operating a Short Path Distillation Setup: Best Practices

Some adjustments can refine your short path distillation setup for optimal efficiency. Here are the best practices to implement:

- Temperature Control: Start the distillation process at a low temperature. It will prevent sudden boiling or degradation of the material.

- Vacuum Management: Vacuum is necessary for lowering the temperature. Choose a system that allows an easy way to maintain a stable vacuum before heating. Furthermore, you should adjust vacuum levels to fine-tune the distillation process.

- Fraction Collection: Change receiving flasks at precise temperature points to separate fractions effectively for high purity.

- Flow Rate: Adjust heating and vacuum components to maintain a steady, controlled flow rate for consistent results.

- Cooling Efficiency: Ensure adequate coolant flow to the condenser and maintain consistent temperature to prevent incomplete condensation.

- Residue Management: To ensure high purity, always remove residues promptly to prevent buildup and contamination. Also, clean the apparatus thoroughly between runs.

By adhering to these practices, producers can maintain consistency and achieve high purity levels in the short path distillation process.

Common Applications of Short Path Distillation

Several industries benefit from short path distillation. Here are some common applications:

- Essential Oil Purification: In the essential oil industry, the process is used to separate and refine essential oils without thermal degradation. It is beneficial for producing high-grade aromatherapy and perfumery ingredients.

- Cannabinoid Extraction: Short path distillation is useful in producing pharmaceutical-grade cannabis extracts. It can effectively isolate and purify CBD, THC, and other cannabinoids.

- Fragrance Production: Distilling and concentrating fragrance compounds helps create pure, potent fragrance bases for perfumes.

- Pharmaceutical Industry: Short path distillation is used to concentrate heat-sensitive medicinal compounds, such as purifying active pharmaceutical ingredients (APIs).

- Food and Beverage Industry: The process concentrates flavors and aromas and purifies edible oils and fats.

Critical Challenges in Short Path Distillation and How to Overcome Them

Short path distillation, while highly effective, has some associated key challenges. Here are the most common issues producers face and how to overcome them.

- Maintaining Vacuum Integrity

One of the common challenges in short-path distillation is maintaining a leak-proof system. A simple solution to this problem is regularly checking all connections, using high-quality vacuum grease, and performing leak tests before each run. - Managing Heat Distribution

Uneven heating can lead to inconsistent results and distillate quality. That’s why producers must use well-designed heating mantles, consider adding insulation, and monitor temperature at multiple points. - Residue Buildup

If you run multiple distillation cycles, dealing with residue buildup can be challenging. Residues can accumulate and affect subsequent distillations. It would help if you implemented a thorough cleaning protocol between runs. Use appropriate solvents and mechanical cleaning when necessary. - Optimizing Fractional Collection

Separating closely boiling fractions can be difficult. If you plan to extract multiple compounds, use precise temperature control, adjust vacuum levels, and consider adding a fractioning column for challenging separations.

Safety Considerations in Short Path Distillation

Depending on the size and components of the short path distillation equipment, you should implement a safety protocol that considers the following:

- Handling Flammable Materials

Ensure workers work in a well-ventilated area or under a fume hood. In the facilities with flammable materials, keep fire extinguishing equipment readily available. Avoid open flames and use explosion-proof electrical equipment. - Managing High Temperatures

Use appropriate personal protective equipment (PPE), including heat-resistant gloves. Train employees to handle heating equipment by allowing it to cool before handling or cleaning. - Ensuring Proper Ventilation

As the short path, distillation process creates vapors, it operates in areas with adequate airflow. Use local exhaust ventilation systems when working with volatile or toxic substances. - Vacuum System Safety

Regularly inspect vacuum lines and connections for wear or damage in order to prevent wear and tear, and use traps to prevent liquids from entering the vacuum pump. - Chemical Handling

Familiarize yourself with the Safety Data Sheets (SDS) for all materials. It contains information about appropriate containment and disposal methods for chemicals.

Conclusion

Short path distillation is preferred in several industries because it efficiently produces high-purity compounds while preserving heat-sensitive materials. From cannabis essential oil refinement to pharmaceutical production, the versatility and precision of the process make it appropriate for superior product quality.

Producers can ensure superior product quality and efficiency by understanding how short path distillation works and its setup. Root Sciences short path distillation equipment with automation and digital controls could enhance precision and reproducibility. Whether you’re setting up a small-scale production facility or a large industrial operation, our equipment can meet your requirements.

Check Out Root Science's Equipment Offerings

Lab Scale

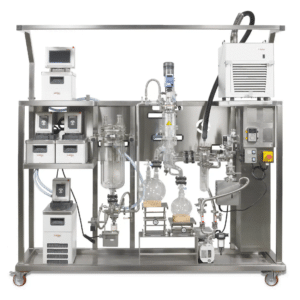

VKL 70-S

The VKL 70-S, the opening model in our VTA line, is the ideal industrial distillation center for cannabis and hemp processing. Designed for efficiency and reliability, the VKL 70-S is perfect for businesses looking to scale their operations. When choosing a suitable machine, the first metric is the amount of material you want to process per shift. The VKL 70-S excels in this regard, yielding an impressive four to five liters of high-quality distillate per shift.

VKL 75

Designed and manufactured in Germany, the VKL 75 is expertly engineered to produce high-quality distillate suitable for a wide variety of market products. As one of the most economical options available, the VKL 75 offers reliable, non-stop production of high-potency distillate, making it an excellent choice for businesses aiming to enhance their efficiency and output. This robust unit yields an impressive four to five liters of distillate per shift, ensuring consistent and efficient processing.

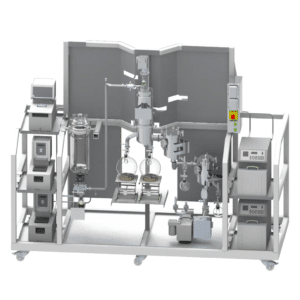

Commercial Scale

VKL 85

The VKL 85 is a premier fully glass wiped-film unit designed for high-capacity, continuous production of superior cannabinoid distillate. Known for its reliability and efficiency, the VKL 85 boasts one of the highest throughputs on the market, typically processing 3.3 liters per hour with a maximum capacity of 4.25 liters per hour. Manufactured in Germany, this machine is engineered to deliver exceptional distillate quality, making it ideal for a wide range of market products.

VKS 90-S

The VKS 90-S is one of the most economical mid-sized options for the reliable production of valuable cannabinoid distillate. Designed and manufactured in Germany, the VKS 90-S yields around twelve liters of distillate per shift, making it an excellent choice for businesses seeking efficient and consistent production.

VKS 95

The VKS 95 is a top-tier wiped-film unit designed for reliable, continuous production of high-quality cannabinoid distillate. It meets high-volume processing needs with a throughput capability of up to 14.27 liters per hour. The fully jacketed system ensures consistent heating, while the true continuous feed feature allows precise control over operation. Discover how the VKS 95 can revolutionize your distillation process and enhance production efficiency.

Industrial Scale

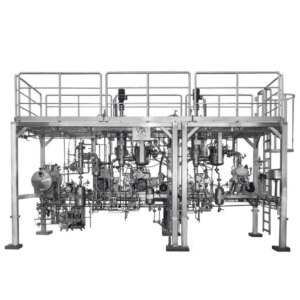

VKS 125

The VKS 125 is one of the largest commercial cannabis distillation units on the market, offering high customization options such as integrated advanced controls and multiple distillation stages. With its impressive throughput capability of up to 20 liters per hour and a fully jacketed system, this machine guarantees a seamless and continuous operation. Discover the unparalleled capabilities of the VKS 125 and elevate your production efficiency.

VK 200-40

At the top of Root Sciences’ standardized line is the VK 200-40, boasting the ability to produce approximately 280 liters of distillate per shift. As the flagship offering in the VTA lineup, this advanced cannabis distillation equipment is ideal for processors requiring extra-large production capacities. The VK 200-40 operates in semi-automatic mode, ensuring unparalleled efficiency and output.

Custom Cannabis Distillation Equipment

Root Sciences offers custom-built VTA equipment options tailored to any scale of processing operations. Our cannabis distillation machines can be customized to meet the specific needs of even the largest processing facilities. Whether you require specialized features or unique configurations, our build-to-suit solutions ensure that your equipment is perfectly aligned with your production goals.