One of the biggest challenges in the extraction industry is managing solvent waste. The decision between solvent disposal and recycling decides how companies meet their compliance, and above all, it’s about balancing economic viability with environmental responsibility. Companies must strategically evaluate their solvent waste solutions as regulatory scrutiny increases and disposal costs rise.

This article examines the factors to consider when choosing between recycling and disposal of waste solvents.

Sections

ToggleUnderstanding Solvent Waste

Solvent waste is the chemicals that get contaminated during extraction and cannot be recycled into the process. These chemicals dissolve, clean, or carry other substances, including hydrocarbons and organic compounds like acetone, methanol, toluene, xylene, and butane. Classified as hazardous waste under environmental regulations, their proper disposal is mandatory because any mismanagement of solvent disposal can lead to severe legal penalties, ecological damage, and health risks.

What is Solvent Recycling?

Solvent recycling is purifying used solvents by removing contaminants, allowing recycled material to be reused in manufacturing or cleaning operations.

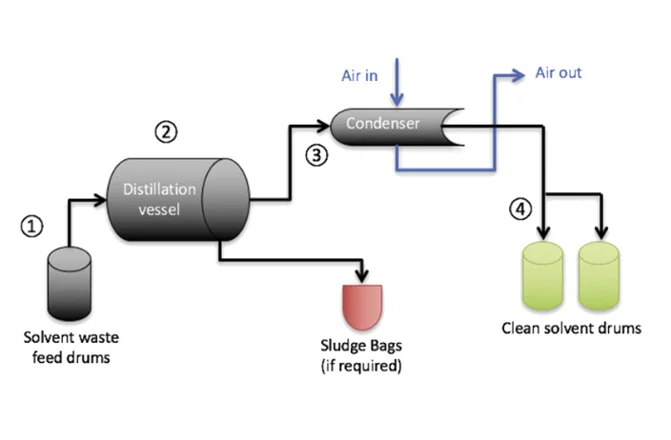

Steps in Recycling:

- Collection – Used solvents are separated and stored

- Separation – Filtration or centrifugation is used to remove solid contaminants from solvent waste

- Distillation – Thermal separation is used to isolate pure solvents from contaminants

- Reuse – Purified solvents are returned to the production cycle

Benefits of Recycling:

- Cost-efficient – Waste solvent recycling significantly reduces the need to purchase new materials

- Eco-friendly – Solvent waste is harmful to the environment, and recycling minimizes their environmental impact

- Supports circular economy – Waste solvent recycling embodies sustainable business practices, emphasizing reuse rather than discarding

Common Recyclable Solvents:

- Acetone and MEK (Methyl Ethyl Ketone)

- Alcohols (Isopropyl, Ethanol, Methanol)

- Hydrocarbons like Butane and Propane

- Mineral Spirits and Paint Thinners

- Chlorinated Solvents (like Perchloroethylene)

What is Solvent Disposal?

Solvent disposal involves safely discarding waste solvents with a thorough treatment to neutralize hazardous properties and prevent environmental contamination.

Steps in Disposal:

- Collection -Solvent waste is collected in containers appropriate for hazardous waste

- Classification – Solvents collected are categorized according to their chemical properties, hazard level, and applicable regulations

- Transport – Licensed waste haulers transfer and move the waste to authorized treatment, storage, or disposal facilities

- Treatment – Depending on the composition, solvents are stabilized, incinerated, or chemically neutralized

Benefits of Disposal:

- Immediate waste removal – Solvent disposal eliminates hazardous materials on-site, reducing risk

- Lower upfront costs – Disposal avoids investment in recycling equipment

- Simpler execution – Waste solvent disposal is much more straightforward to execute than recycling

- Essential for regulatory compliance – Certain highly hazardous solvents must be disposed of as a legally permissible option

Common Solvents Requiring Disposal:

- Heavily contaminated mixed solvents

- Solvents containing heavy metals or PCBs

- Halogenated solvents

- Adhesive residues

- Solvent with unknown composition

Solvent Waste Recycling vs. Disposal: Quick Comparison

Factor | Recycling | Disposal |

Environmental Impact | Minimizes waste generation Reduced carbon footprint of the extraction process | Generates more waste Requires energy for treatment processes increasing carbon footprint |

Cost Over Time | Higher initial investment required for recycling equipment Long-term savings on material purchases | Lower upfront costs Continuous expenses for waste removal |

Compliance & Regulations | By reducing hazardous waste materials, it reduces the regulatory burden on companies | High compliance requirements needing strict adherence to waste manifesting and disposal regulations |

Resource Utilization | Maximizes value recovery from used materials | Represents a total loss of resource value |

Ease of Implementation | More complex systems and equipment are required Staff with technical expertise required for operations | Simpler to execute in partnership with established waste disposal vendors |

Ideal For | High-volume solvent waste generators with consistent waste streams | Small-volume solvent waste generators or those with highly contaminated solvents |

Factors to Consider When Choosing

- Volume of Solvent Waste

The volume of solvent waste significantly influences the decision to recycle or dispose of solvent. If waste produced is in high volumes, it justifies investment in recycling equipment. Setting up recycling may not be justified for smaller operations generating minimal waste solvents.

- Type and Composition of Solvents

Not all solvents can be recycled. Less contaminated, single-solvent waste is ideal for solvent recycling, while heavily contaminated or mixed solvents may be better suited for solvent disposal. Also, the solvent’s chemical properties decide the feasibility and cost-effectiveness of recycling versus disposal options.

- Space and Infrastructure Availability

A solvent recycling facility setup requires dedicated space and utilities like electricity and cooling water. Companies with space constraints will find solvent waste disposal more practical than installing recycling systems on-site.

- Regulatory Requirements

Regulatory laws regarding solvent waste disposal and recycling may affect the decision depending on the facility’s location. Most governments offer incentives for recycling, while some jurisdictions impose strict requirements on recycling facilities. The local regulatory environment must be understood when exploring solvent waste solutions.

- Sustainability and ESG Goals

Responsible companies include environmental performance metrics in their corporate goals. Waste solvent recycling can contribute to these goals by reducing waste generation and raw material consumption.

Compliance and Regulations

- Hazardous Waste Laws

Most solvent waste is considered hazardous material, requiring strict adherence to storage, handling, and documentation requirements.

- Regulatory Bodies

Agencies such as the Environmental Protection Agency (EPA) and State Environmental Agencies like California’s Department of Toxic Substances Control decide and oversee compliance with hazardous waste regulations.

- Permits & Documentation

Solvent recycling and disposal require proper permission from authorities depending on the methods employed.

- Certified Vendors

Compliant solvent waste disposal requires hiring licensed waste solvent disposal companies or recyclers.

- Inspections

Regulatory authorities regularly audit recycling and disposal companies to verify solvent waste management regulations compliance.

Cost Comparison

Cost Element | Recycling | Disposal |

Equipment Setup | Recycling equipment may require a significant initial investment ($30,000-$500,000) | Minimal upfront costs, only spend on storage containers |

Operational Costs | Operating a recycling facility requires energy, labor, maintenance, and testing. However, it also offsets the spending by reducing the purchase of new solvents | Ongoing disposal fees which can cost anywhere between $3 to $10 per gallon of solvent waste |

Compliance & Reporting | Reduced manifesting as a solvent waste generator but added equipment compliance costs | Regular manifesting and cradle-to-grave documentation requirements |

Long-Term Financial Impact | Typically cost of equipment is recovered within 1-5 years depending on solvent waste volume | Consistently spending and increasing costs as disposal fees rise |

Environmental Impact

- Resource Conservation

Solvent recycling preserves valuable petrochemical resources and reduces the environmental impact of extracting and refining raw materials.

- Carbon Footprint

Producing virgin solvents is highly energy-intensive; hence, waste solvent recycling significantly reduces greenhouse gas emissions.

- Pollution Prevention

Proper solvent waste management is essential to prevent soil and groundwater contamination.

Conclusion

Whether a company chooses solvent recycling or solvent disposal will significantly impact its financial performance and environmental responsibility. Waste solvent recycling offers long-term cost and sustainability benefits but requires more significant initial investment and technical capability. With solvent waste disposal, upfront costs can be kept low, but it results in ongoing expenses and more significant environmental impact.

Based on all factors, for many companies, the optimal solution is to take a hybrid approach. Recycling easily recoverable solvents while utilizing and disposing of contaminated or mixed solvents offers a solvent waste solution that balances economic, operational, and environmental considerations.