The legal status of cannabis-derived products remains a challenge. While there is increasing legalization of cannabis in states at the federal level, it remains a scheduled substance. However, the law allows manufacturers to produce and market cannabis-based products provided they adhere to some requirements.

With the evolving cannabis and hemp industries, THC remediation has become crucial for product compliance and consumer safety. In this article, we explore the intricacies of THC remediation, its definition, methods, challenges, and prospects.

Sections

ToggleWhat is THC Remediation?

THC remediation is the process of reducing or eliminating THC (tetrahydrocannabinol) content in hemp or cannabis-derived products to meet legal requirements. Producers of hemp-derived products in the United States must follow the 2018 Farm Bill that legalized hemp cultivation. The bill stipulates that hemp products must contain less than 0.3% THC by dry weight. While most of the states have strict regulations requiring zero-THC content in hemp-derived products, the states of Kansas and Georgia allow up to 5% THC in medical cannabis products.

THC remediation has become the cornerstone in the cannabis industry to ensure that CBD, hemp or other cannabinoid products comply with the standards set for consumer safety.

THC in Hemp vs. Cannabis

Aspect | Hemp | Marijuana |

THC Concentration | Typically less than 1% | Can range from 15% to 30% |

Post-Extraction THC Levels | Can exceed the legal limit of 0.3% | Typically remains high |

Legal Distinction | Requires THC remediation to meet <0.3% THC | Classified as marijuana due to high THC |

Role of THC Remediation | Reduces THC to meet legal requirements | Not applicable for marijuana products |

Popular Methods of THC Remediation

There are several ways of THC remediation for manufacturers to choose from. It depends on what product is processed to lower its THC concentrations.

Let’s take a look at the popular THC remediation methods:

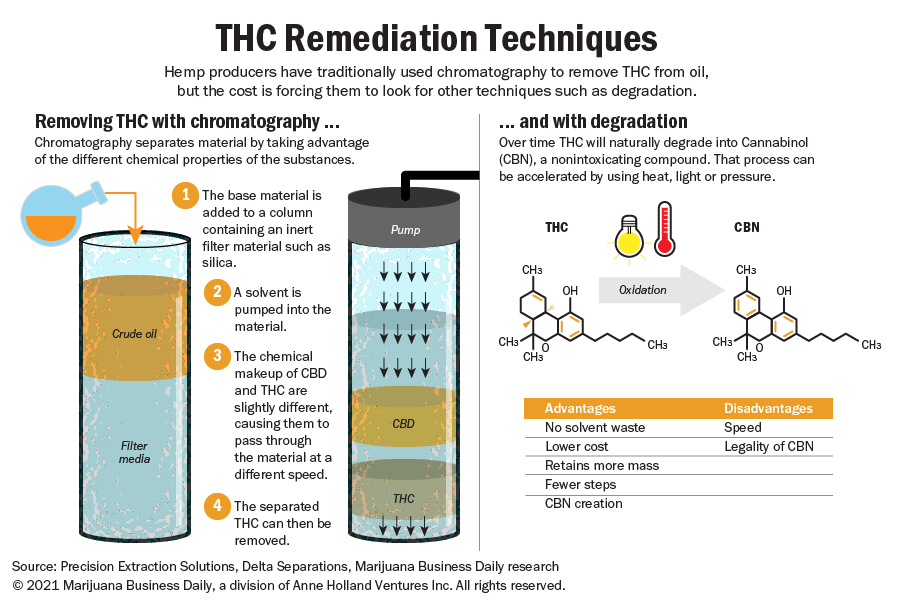

1. Chromatography-Based Techniques:

- Flash and Reverse-Phase Chromatography: The chemical separation technique separates chemical mixtures. Flash and reverse-phase chromatography methods utilize stationary and mobile phases to separate compounds based on their molecular properties.

Flash chromatography involves forcing a solvent through a column under pressure. The column, filled with silica gel or alumina, helps separate compounds. Reverse-phase chromatography uses a non-polar stationary phase and polar mobile phase to separate THC from CBD and other cannabinoids.These THC remediation techniques have high precision and efficiency, but the setup and equipment costs can be expensive.

- Countercurrent Chromatography: This method employs liquid-liquid separation to isolate THC from other cannabinoids. The setup uses a centrifugal pump to retain one liquid phase while allowing another to flow, separating the compounds. As compared to other chromatography methods, it leads to reduced THC loss.

2. Non-Chromatography Alternatives:

- Crystallization: This THC remediation method involves crystallizing CBD to isolate it from THC and other impurities. CBD crystals are formed by manipulating temperature and solvent conditions, leaving THC and other compounds in the liquid phase. This method is used to produce high-purity CBD isolates achieving deficient THC levels.

- Conversion Techniques: These remediation methods convert THC into other compounds, effectively reducing its concentration in the final product. One widely used conversion technique is UV degradation, which exposes the extract to ultraviolet light. This converts THC to CBN (cannabinol). Another method is heat oxidation, which uses controlled heat to degrade THC into other compounds. While these techniques are effective, they can degrade CBD and other desired compounds and may alter the overall cannabinoid profile of the product.

3. Innovative Molecular Engineering:

Innovation is at the helm of the progress of the cannabis industry. An innovative THC remediation technique is Affinity Nanotechnology, as developed by Sixth Wave Innovations, which uses molecularly imprinted polymers (MIPs) to capture THC molecules selectively. This automated process can remediate THC on a large scale with high efficiency.

Challenges in THC Remediation

THC remediation techniques present several challenges that manufacturers must prepare for. Here are the primary challenges faced:

1. Technical and Financial Barriers

Most of the THC remediation methods require specialized equipment, which can have high costs. It requires substantial upfront investment, which can be prohibitive for smaller producers. Also, operating complex remediation systems demands highly trained personnel. It increases labour costs and operational costs.

2. Quality Control and Consistency

Given the strict requirement to maintain <0.3% THC threshold in products consistently, it can be challenging as the source material can have varying levels of THC content, which will need fine-tuning the setup regularly. Furthermore, some THC remediation methods may inadvertently degrade other cannabinoids or introduce impurities. It can affect the overall quality and efficacy of the final product.

3. Efficiency and Yield Loss

THC remediation results in some loss of desired compounds; this lowers overall yield and increases production costs. Also, scaling up remediation processes as the demand for THC-free products grows can be challenging without compromising efficiency or quality.

THC Remediation Applications

THC remediation remains crucial for the legal validity of the end products. It is used to control THC content percentage in several kinds of products.

- CBD Isolates: These extracts undergo the most rigorous THC remediation to achieve 99%+ purity. They only contain CBD with virtually no other cannabinoids or compounds.

- Distillates: Distillates are broad-spectrum extracts with a range of cannabinoids and terpenes, with no THC. They offer a middle ground between isolates and full-spectrum products.

- Full-Spectrum Products: These are hemp-based extracts that undergo minimal remediation to maintain a natural cannabinoid profile while still meeting the <0.3% THC requirement.

Advanced THC Remediation Equipment by Root Sciences

Root Sciences provides cutting-edge THC remediation equipment designed to help producers meet regulatory compliance while maintaining product quality. Its advanced systems, including HPLC systems and Axial Compression Columns, are engineered for precision, scalability, and efficiency.

HPLC Systems:

MetaPür’s High-Performance Liquid Chromatography (HPLC) systems are optimized for purification processes, offering flexibility with multiple column media types. Key features include advanced UV detection, multi-column capabilities, and compliance with stringent industry regulations, ensuring reliable THC removal and cannabinoid isolation.Axial Compression Columns:

MetaPür’s axial compression columns ensure uniform flow distribution for optimal chromatography performance. These columns are easy to unpack and repack, improving efficiency and achieving higher purity and yield during THC remediation processes.

Speak with an Expert About Your THC Remediation Needs

Industries and Consumers Benefiting from THC-Free Products

THC remediation becomes a necessity to avail cannabis products to consumers across industries with minimal THC risks.

- Transportation sector: As employees in this sector are subject to drug testing, they can use THC-free CBD products without risking positive results.

- Healthcare: Patients seeking therapeutic benefits of cannabis without psychoactive effects or drug interactions.

- Professional athletes: As athletes are subject to strict anti-doping regulations, they can benefit from THC-free CBD for recovery and pain management.

- Individuals with THC sensitivity: Some consumers may experience adverse reactions to THC and prefer completely THC-free options.

The Future of THC Remediation

As there is growing demand for THC-free cannabis products, manufacturers are exploring advances in selective breeding to develop hemp strains with naturally low THC content. These efforts aim to reduce or eliminate the need for post-extraction THC remediation. By selectively breeding plants with desired cannabinoid profiles, we can produce hemp with <0.3% THC threshold without additional processing.

Several innovative technologies are on the horizon, such as continuous flow remediation systems for cost-effective THC removal and AI-driven process optimization to fine-tune remediation parameters.

Conclusion

THC remediation is a crucial process for manufacturers in the cannabis industry to produce compliant, non-psychoactive CBD products. Knowledge of the methods and technologies used for THC removal can help producers overcome challenges that persist in terms of cost, efficiency, and scalability.