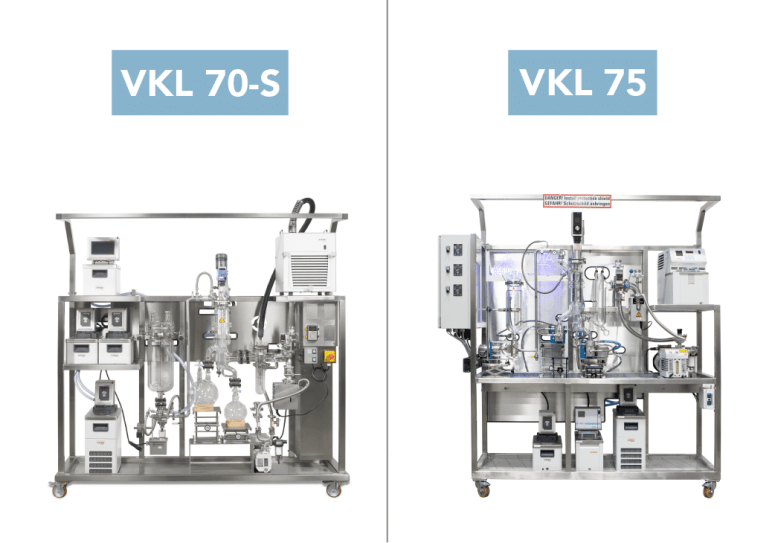

The production of superior distillate for various products is the hallmark of Root Sciences’ molecular distillation plants. Their VKL 70-S and VKL 75 machines are designed and manufactured in Germany by renowned equipment manufacturer VTA. While both options cater to businesses searching for high-quality distillate, it’s essential to consider the differences between the types of cannabis distillation equipment before choosing one that best suits your needs.

How The VKL 70-S and VKL 75 Compare

Broadly speaking, the VKL 70-S is designed as the entry-level unit in this throughput range, whereas the VKL 75 is the fully featured premium version. So, the VKL 70-S is priced to please a more budget-conscious customer, and the VKL 75 incorporates all of the latest technology while still maintaining an attractive price point.

The VKL 70-S and the VKL 75 are very similar, but there are some subtle differences that set these two units apart in a big way. Let’s first look at the similarities between the two units:.

- Electrical requirements

- Heating and chilling capacities

- Upgrade options such as a -100 °C immersion cold trap, 5 L feed vessel, and an additional TCU heater for the residue arm (recommended for CBD distillation)

- Floor space and work area requirements

- Evaporator surface area (0.05 m2)

- GMP: material certificates, FDA certificates, IQ, OQ, FAT, SAT protocols available

- Full onsite training, commissioning, lifetime technical support

Now let’s delve into the differences between these two systems.

The VKL 75 uses gear pumps to dispense the residue and distillate streams to open air (i.e. not under vacuum) for collection during production. This reduces downtime and consistently provides a throughput of around 1.3 liters per hour. On the other hand, the VKL 70-S utilizes ball flasks under vacuum to capture residue and distillate, thus resulting in up to 25 minutes of stoppage time for collection.

Additionally, these two systems differ in their mode of operation. The VKL 70-S implements a rolled film distillation method, while the VKL 75 utilizes a wiped film approach. Both effectively spread a thin layer of material on the evaporator column. Yet, one might suit certain starting mixtures better than the other or be preferred in various settings. There are also specific features that make one or the other ideal for different applications. However, both units have the ability to create a high-quality distillate with a purity upwards of 90% (starting material dependent).

With precision engineering and manufacturing, these distillation plants produce versatile distillates that can be used in various products available in today’s market. To find out which equipment best fits your company’s needs, get in touch with Root Sciences today. Root Sciences is the global leader in the distribution of end-to-end equipment and support services for processing facilities in the cannabis and hemp industries, providing premium extraction, distillation, and other post-processing technologies, as well as business planning and lab/facility design and consulting services. Want to know how to make cannabis distillate? Check out this blog post.