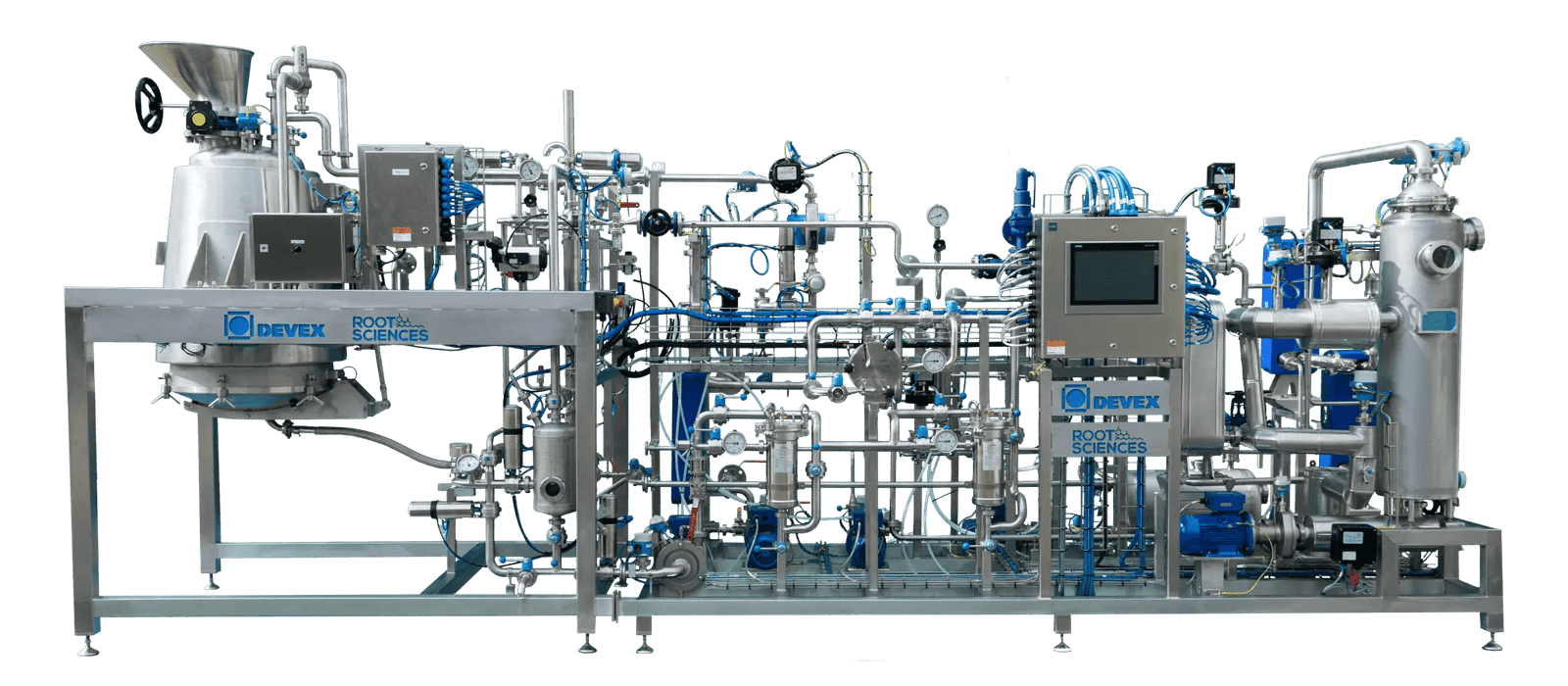

CryoEXS 400 Cryogenic Ethanol Extraction Equipment

All-In-One Cryo-Ethanol Extraction Solution

The CryoEXS 400 is an all-in-one system, which provides several unrivaled benefits:

- Equipment Included: No need for separate equipment for winterization, solvent recovery, decarboxylation, or devolatilization

- Rapid Process: Processing time is reduced from several days to several hours

- Reduced Labor: Fewer operators are required, saving on labor costs

- Scalable, Skidded System: Scalable, skidded system with 400, 800, and 4,000 lb throughput (per 8-hour shift) options

- Automation: State-of-the-art sensors, controllers, and simple touch-screen interface allow a single operator to monitor the system

Specifications

| Extraction | Extractor: 1 x 300 L Solvent: Ethanol (other solvents on request) Extraction Temperature: -40°C |

| Evaporation | Evaporation Capacity: 264 kg/h ethanol (350 L/h) Feed Quantity: 100 – 800 kg/h (variable) Solvent: Ethanol Evaporation Pressure: 50-600 mbar (abs) |

| Electrical Specifications | Mains Requirements: 3Φ 480 V, N+PE, 60 Hz Power Consumption: 67.5 kW |

| Facility Requirements | Ambient Air Temperatures: 5 – 40°C Ambient Humidity: 25 g/kg dry air (90% RH) Machine Dimensions: 17.62′ x 5.09′ x 7.97′ (L x W x H) |

key features

- Throughput Capability: 400 lb per 8-hour shift

- GMP Ready: Made with cleanliness, efficiency, and reliability in mind, with tailored GMP documentation included

- The Complete Solution: Skidded, scalable system automatically performs solvent cooling, extraction, biomass desolventization, extract filtration, solvent recovery, and decarboxylation

- Reliable, Powerful Chilling: Reliable refrigeration solutions provided by industry-leading experts, trusted by companies like Tesla, BP, Apple, Coca-Cola, among others

- Modular Filtration: Negating the need for winterization, our modular and reconfigurable filtration assembly allows for flexibility, and easy maintenance, cleaning, and element replacement

- Evaporation and Decarboxylation: Efficient solvent recovery capacity at a sustained 350 liters per hour, this essential function is highly automated, enabling reliable continuous operation

- Energy Efficiency: Recaptures latent heat from cold ethanol after extraction, translating into a lower utility bill and ensuring the lowest possible cost of operation

- Materials Conveyance: Capable of integrating into an automated materials conveyance system allowing for sanitary operation with automated biomass input and product discharge

- Expert On-Site Training: Detailed Standard Operating Procedures included for operation, maintenance, and troubleshooting of equipment

- Service and Maintenance: Service packages to keep equipment in top operational condition

ROI / Estimated Payback Period

| Material |

Cannabis |

Hemp |

Cannabis |

Hemp |

| Daily Processing Time |

8-hour (one shift) |

24-hour continuous (three shifts) |

||

| Daily Concentrate Yield |

26 kg |

77 kg |

||

| Daily Concentrate Value |

$77k |

$26k |

$230k |

$78k |

| Payback Period |

22 days |

68 days |

8 days |

23 days |

How is Cryo-Ethanol Extraction Unique?

Cryo-Ethanol extraction is the most efficient and cost-effective solution for large-scale cannabis processors. The cannabinoid-rich crude extract that is produced is ideal for further refinement into high purity distillates and isolates.

Traditionally, the most common extraction methods used in the creation of cannabis crude oil have been CO2 extraction, light hydrocarbon extraction, and warm ethanol extraction. CryoEXS, entered the hemp and cannabis extraction market in 2019, cutting the extraction process down from days to hours by utilizing cryo-ethanol extraction (commonly referred to as cold-ethanol extraction) technology.

CryoEXS efficiently leaves all lipids behind during the extraction process, which allows processors to cut the process bottleneck down from a few days to just a few hours. Manufactured by DEVEX of Germany, our cryo-ethanol extraction systems provide the benefit of bypassing several steps that must be followed during other extraction methods. This type of cold-ethanol extraction technology offers a much more advantageous and time-efficient solution to the extraction process.