Advanced Cannabis Ethanol Extraction Solutions

Root Sciences provides advanced ethanol extraction equipment designed for efficient, high-yield cannabis concentrate production. This scalable method preserves cannabinoids like CBD and THC while removing unwanted compounds, making it a preferred choice for producing premium extracts. Known for its safety, versatility, and ability to process large biomass volumes, ethanol extraction helps businesses streamline operations while maintaining compliance and consistency.

Equipment Offerings

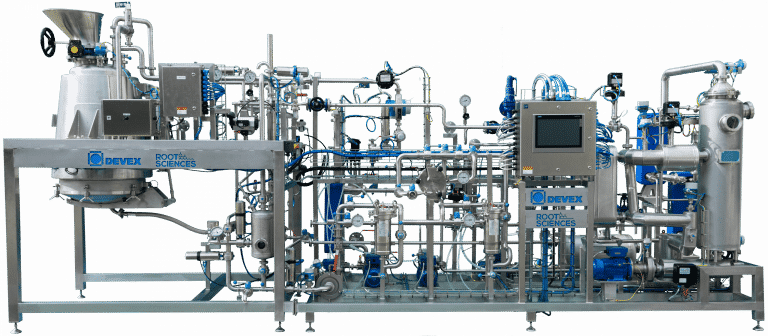

CryoEXS

Root Sciences’ CryoEXS technology revolutionizes hemp and cannabis processing by reducing the extraction process from days to just a few hours. Manufactured by DEVEX of Germany, this cryo-ethanol (cold-ethanol) extraction system streamlines production by bypassing multiple steps required by alternative methods. Offering a time-efficient, sustainable solution for pre-distillation of crude cannabis oil, CryoEXS is ideal for pharmaceutical-grade facilities looking to optimize their extraction process with high precision and reliability.

EFR

The EFR is the cannabis and hemp industry’s only closed-loop, all-in-one ethanol extraction solution, offering extraction, filtration, and solvent recovery in one semi-automated, user-friendly system. Capable of processing 30-60 pounds of biomass per hour, the EFR is designed to fit within current and future extraction facilities, meeting all regulatory compliance requirements, including C1D1 and C1D2 certifications. With its compact, modular design and in-line filtration down to 0.5 micron, the EFR ensures efficient, high-yield extraction with 95-98% ethanol recovery. Proudly engineered in Denver, USA, it offers GMP and GPP compliance for safe and scalable operation.

Ethanol extraction is a highly efficient and widely used method in the cannabis industry for extracting cannabinoids, terpenes, and other valuable compounds from cannabis and hemp plants. The process involves using food-grade ethanol as a solvent to separate the desired compounds from the plant material, creating a high-quality crude extract that can later be refined into concentrates, oils, and distillates. Ethanol is a preferred solvent due to its ability to extract a wide range of cannabinoids and terpenes while minimizing the presence of undesirable components, such as chlorophyll and waxes.

Ethanol extraction can be performed at room temperature, but when done using cryogenic (sub-zero) temperatures, it reduces the need for additional filtration steps, saving time and effort. This cold-ethanol process is especially useful for preserving the integrity of the extract, ensuring a clean and potent final product. The method’s scalability makes it ideal for both small-scale operators and large commercial cannabis processing facilities.

In addition to being efficient, ethanol extraction is known for its safety and cost-effectiveness. Closed-loop systems, such as those offered by Root Sciences, ensure that the solvent is fully recovered and reused, reducing waste and operational costs. Furthermore, ethanol extraction systems are typically designed to meet regulatory standards, including C1D1 and C1D2 compliance for safety in hazardous environments.

By incorporating ethanol extraction into their processes, cannabis producers can achieve high throughput and consistent, reliable results, making it one of the most trusted methods for producing high-quality cannabis concentrates and oils.

Ethanol extraction is one of the most effective and scalable methods used in the cannabis industry to produce high-purity concentrates. This process leverages ethanol as a solvent to separate cannabinoids, such as THC and CBD, along with terpenes, from the plant material. Ethanol’s unique chemical properties allow it to dissolve these valuable compounds efficiently while minimizing unwanted substances like chlorophyll and waxes, resulting in a cleaner extract.

A key advantage of ethanol extraction is its ability to preserve a broad range of cannabinoids and terpenes, making it a preferred method for full-spectrum and broad-spectrum cannabis products. By carefully controlling temperature and solvent-to-biomass ratios, processors can fine-tune the extraction to optimize purity, potency, and consistency. Unlike other extraction methods that may require complex post-processing to remove residual solvents, ethanol evaporates easily, reducing the need for additional refinement.

Ethanol extraction is also highly scalable, making it an ideal choice for both small-batch craft producers and large-scale cannabis manufacturing facilities. The process is widely regarded for its efficiency, safety, and regulatory compliance, aligning with Good Manufacturing Practices (GMP) and other industry standards. As the cannabis market continues to expand, ethanol extraction remains a cornerstone of high-quality cannabis oil production, offering a balance of cost-effectiveness, high throughput, and product integrity.

Root Sciences provides advanced ethanol extraction equipment engineered for precision and reliability, ensuring businesses can optimize production while maintaining the highest standards of quality and efficiency.

Ethanol extraction is a widely used method in the cannabis industry due to its efficiency, scalability, and ability to produce high-purity extracts. Here are the key advantages:

- High Extraction Efficiency

Ethanol effectively dissolves a broad range of cannabinoids and terpenes, leading to high extraction yields. It is particularly effective for producing full-spectrum and broad-spectrum extracts, as it preserves the plant’s beneficial compounds while minimizing unwanted elements like chlorophyll and waxes. - Scalability for Large-Scale Production

Ethanol extraction is highly scalable, making it suitable for both small-batch operations and large cannabis processing facilities. This allows businesses to expand production without requiring major modifications to their extraction setup. - Cost-Effective Solvent

Compared to other solvents like CO₂ or hydrocarbons, ethanol is relatively affordable and widely available. It also has a high recyclability rate, meaning processors can recover and reuse the solvent multiple times, reducing operational costs. - Faster Processing Times

Ethanol’s ability to efficiently dissolve cannabinoids and terpenes results in shorter processing times compared to other extraction methods. This increases throughput, making it ideal for high-volume cannabis production. - Safer and More Versatile

Ethanol is considered a safer alternative to hydrocarbon-based solvents like butane or propane, as it has a lower risk of explosion and is less toxic. Additionally, ethanol extraction can be performed at cold temperatures to selectively extract cannabinoids and terpenes while reducing the co-extraction of unwanted plant materials. - Compliance with Industry Standards

Many regulatory bodies, including those governing pharmaceutical and food-grade production, recognize ethanol as a safe solvent. This makes ethanol extraction an attractive choice for cannabis processors looking to meet Good Manufacturing Practices (GMP) and other compliance standards. - Simplified Post-Processing

Unlike other solvent-based extraction methods, ethanol evaporates easily, leaving behind minimal residue. This reduces the need for extensive post-processing and purification, resulting in a cleaner and more efficient workflow.

Choosing the right ethanol extraction equipment is crucial for optimizing efficiency, ensuring compliance, and producing high-quality cannabis extracts. Several factors must be considered to align your equipment with production goals, regulatory requirements, and operational needs.

- Production Scale and Throughput

- Determining how much cannabis biomass you need to process is key. Ethanol extraction systems range from small-batch laboratory units to industrial-scale equipment capable of processing thousands of pounds per day. Selecting the right system ensures scalability and efficiency for your operation.

- Temperature Control Capabilities

- Ethanol extraction can be performed at cryogenic temperatures (-40° C or lower) to minimize unwanted compounds like chlorophyll and waxes, resulting in a cleaner extract. Systems with advanced temperature control provide better selectivity, enhancing cannabinoid and terpene retention.

- Solvent Recovery Efficiency

- Efficient solvent recovery reduces operational costs by reclaiming ethanol for reuse. Look for falling film evaporators or rotary evaporators that enable high-speed ethanol recovery while maintaining product purity. Optimized solvent recycling leads to higher yields and lower waste.

- Compliance and Safety Standards

- Ethanol extraction equipment should meet industry safety regulations such as Good Manufacturing Practices (GMP), cGMP certification, and UL Listing to ensure compliance in regulated markets. Choosing compliant equipment helps streamline licensing and ensures consistent product quality.

- Automation and Workflow Integration

- Automation enhances efficiency and consistency while reducing labor costs. Modern extraction systems feature programmable controls, automated solvent recovery, and real-time monitoring, allowing for seamless operation with minimal manual oversight.

- Compatibility with Post-Processing Equipment

- Ethanol extraction is just one step in cannabis oil production. Ensure your system integrates well with winterization, filtration, decarboxylation, and distillation for a smooth end-to-end process. A well-planned workflow increases efficiency and final product quality.

- Total Cost of Ownership

- Beyond the initial investment, consider the long-term operational costs, including energy consumption, maintenance, and solvent recovery. High-efficiency systems with lower maintenance requirements often provide better ROI over time.

Root Sciences’ Business & Facility Planning Services

Selecting the right equipment can be complex, but Root Sciences offers full-service business and facility planning, including equipment selection and integration. Our team provides expert guidance on designing extraction facilities, optimizing workflows, and ensuring compliance with regulatory standards. Whether you’re launching a new operation or upgrading an existing one, we help you make informed decisions to maximize efficiency and profitability.

- What is ethanol extraction, and how does it work?

- Ethanol extraction is a method used to isolate cannabinoids and terpenes from cannabis biomass. It involves soaking the plant material in food-grade ethanol, which dissolves the desired compounds. The ethanol is then evaporated, leaving behind a purified cannabis extract that can be further refined into various products.

- Why is ethanol extraction preferred over other methods?

- Ethanol extraction is highly efficient, scalable, and cost-effective. It can process large volumes of biomass while preserving a wide range of cannabinoids and terpenes. Additionally, ethanol is safer to handle than hydrocarbon solvents like butane and is widely accepted in regulated markets.

- What is the difference between cold and warm ethanol extraction?

- Cold ethanol extraction (cryogenic temperatures of -40° C or lower) minimizes the extraction of unwanted compounds like chlorophyll and waxes, producing a cleaner extract.

- Warm ethanol extraction can be faster but may require additional post-processing steps, such as winterization, to remove impurities.

- Is ethanol extraction safe?

- Yes, when performed with the proper equipment and safety protocols, ethanol extraction is considered safe. It is widely used in pharmaceutical and food-grade applications due to its low toxicity and high solvent recovery rate.

- What type of ethanol is used in cannabis extraction?

- Food-grade ethanol (often 190-proof or 200-proof) is commonly used. Some processors use denatured ethanol, which contains additives to reduce consumption risk, but it may require additional purification steps.

- How is ethanol recovered after extraction?

- Ethanol is typically recovered using falling film evaporators or rotary evaporators, which separate the solvent from the cannabis extract through controlled heating and vacuum pressure. This allows the ethanol to be recycled for future use, reducing costs.

- What is winterization, and why is it necessary?

- Winterization is a post-extraction process where the extract is mixed with cold ethanol and then filtered to remove fats, lipids, and waxes. This step is especially important for warm ethanol extraction to ensure a cleaner final product.

- How do I choose the right ethanol extraction equipment?

- Selecting the right equipment depends on factors like production scale, temperature control, solvent recovery efficiency, automation, and compliance standards. Root Sciences offers consulting services to help businesses choose the best system for their needs.

- What are the regulatory considerations for ethanol extraction

- Ethanol extraction systems must comply with Good Manufacturing Practices (GMP), cGMP certification, and UL safety standards in regulated markets. Proper facility design, ventilation, and solvent handling protocols are also essential for meeting industry regulations.

- Can ethanol extraction be used for both THC and CBD production?

- Yes, ethanol extraction is effective for producing both THC-rich and CBD-rich extracts, making it suitable for a variety of cannabis and hemp products, including oils, tinctures, and edibles.

- How can Root Sciences help with ethanol extraction?

- Root Sciences provides state-of-the-art ethanol extraction equipment as well as business and facility planning services, helping businesses design, optimize, and scale their extraction operations while ensuring compliance and efficiency.