Industry-leading cannabis closed-loop extraction equipment

For those searching for hydrocarbon extraction machines, Root Sciences offers advanced butane and hydrocarbon extraction systems engineered for efficiency, safety, and premium-quality results. Our closed-loop BHO extractors utilize butane (n-butane, isobutane) and propane to produce high-purity concentrates such as live resin, sauce, and diamonds.

Hydrocarbon Extraction System Offerings

Lab Scale

The miniMeP minimizes reinvestment costs when expanding, making scalability a breeze. Its 10-liter capacity enables you to process 5 pounds of material per run, achieving an impressive throughput of up to 40 pounds every 8 hours.

The MEGA-miniMeP is the ultimate upgrade for your extraction needs. With an impressive 20-liter material capacity, it processes up to 17.5 pounds of material per hour using multiple recovery pump solutions.

Commercial Scale

Introducing the MeP 30 by Extractiontek – the ultimate in extraction versatility. With run sizes from 1 to 15 pounds, this machine easily handles your critical products. It offers an impressive 10-30 liter capacity and can process over 15 pounds of material per hour. Achieving a remarkable throughput of 150 pounds in an 8-hour shift, the MeP 30 revolutionizes production in hydrocarbon extraction.

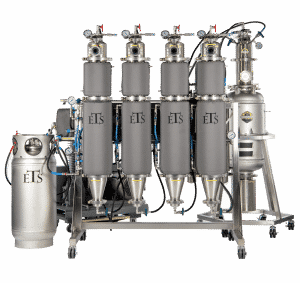

The MeP XT70 by Extractiontek is the pinnacle of high-capacity extraction. With an impressive 70-liter material capacity and independent material columns, it ensures continuous processing. Maximizing efficiency, it redefines industry standards, running propane, butane, and blended solvents for all popular concentrate products. Processing at 30 pounds per hour, the MeP XT70 is the game-changer in hydrocarbon extraction efficiency.

Industrial Scale

The MeP XLE is the ultimate solution for ultra-high-capacity extraction. With versatile material capacity options ranging from 50 to 300 liters, it’s tailored to meet the demands of the modern cannabis industry. Featuring the HFFE Hydrocarbon Falling Film Evaporator by ETS, it ensures efficient solvent recovery.

| Model | miniMeP | MEGA-miniMeP | MeP 30 | MeP XT70 |

|---|---|---|---|---|

| Maximum Capacity | 2.27 kg | 4.52 kg | 6.81 kg | 15.89 kg |

| Throughput | 2.27 kg/h | 4.42 kg/h | 6.81 kg/h | 15.89 kg/h |

| Dimensions (LxWxH) | 3’ x 3’ x 5’ | 3’ x 3’ x 5’ | 5’ x 3’ x 5’ | 11’ x 3’ x 6.5’ |

| Certifications | ASME SECTION Viii, IFC, NFPA 58, 3-A Sanitary Standard, CLASS I DIVISION 1, NSF and UL21 | ASME SECTION Viii, CRN, IFC, NFPA 58, 3-A Sanitary Standard, CLASS I DIVISION 1, NSF and UL21 | ASME SECTION Viii, IFC, NFPA 58, 3-A Sanitary Standard, CLASS I DIVISION 1, NSF and UL21 | ASME SECTION Viii, CRN, IFC, NFPA 58, 3-A Sanitary Standard, CLASS I DIVISION 1, NSF and UL21 |

This method employs specific hydrocarbons, such as propane and butane, as solvents. These solvents, when mixed with cannabis, effectively extract valuable chemical compounds from the plant. The resultant product is then subjected to additional refinement processes. The final, highly concentrated extracts are used in various forms like cannabis oils, shatter, glass, hash, and wax. When executed correctly in a commercial setting, these extracts have minimal to no hydrocarbon residues.

- Pre-extraction preparation: The raw material is prepared by grinding and drying to ensure optimal extraction efficiency.

- Extraction phase: Hydrocarbons like butane or propane are used to dissolve the desired compounds from the raw material.

- Filtration and purification: The solution is filtered to remove any unwanted plant material and impurities.

- Ethanol recovery: Ethanol is used to further purify the extract, which is then recovered and reused in the process.

- Purging: Removing residual hydrocarbons to ensure the safety of the concentrate.

- Post-processing steps: Techniques like winterization and distillation are employed to refine the extract, removing fats, waxes, and other impurities.

- Efficiency: Hydrocarbon extraction equipment is designed to maximize yield and minimize processing time, making it highly efficient.

- Purity of extracts: This method produces high-purity extracts, ensuring that the final product is of the highest quality.

- Versatility: Hydrocarbon extraction equipment can be used with various solvents and raw materials, making it a versatile choice for different extraction needs.

- Cost-effective: The equipment is often more affordable compared to other extraction methods, providing a cost-effective solution for businesses.

- Scalability: Suitable for both small-scale and large-scale operations, allowing businesses to scale up production as needed.

Points To Keep In Mind While Choosing Hydrocarbon Extraction Equipment

- Scale of operation: Determine the size of your operation to choose equipment that meets your production needs.

- Budget: Consider your budget to find equipment that offers the best value without compromising on quality.

- Desired product quality: Ensure the equipment can produce extracts that meet your quality standards.

- Safety considerations: Look for equipment with robust safety features to protect operators and ensure compliance with regulations.

- Ease of use: Choose equipment that is user-friendly and requires minimal training for operators.

- Maintenance and support: Opt for equipment that comes with reliable maintenance and customer support services.

- What safety measures should I take when using hydrocarbon extraction equipment?

Ensure proper ventilation, use explosion-proof equipment, and follow all safety protocols to prevent accidents. - Can hydrocarbon extraction equipment be used for both butane and propane?

Yes, most hydrocarbon extraction equipment is compatible with both butane and propane. - What is the difference between hydrocarbon extraction and other extraction methods like CO2 or ethanol?

Hydrocarbon extraction is typically faster and can produce higher yields, while CO2 extraction is known for its safety and ethanol extraction for its cost-effectiveness. - How long does the hydrocarbon extraction process take?

The process can take anywhere from a few hours to a full day, depending on the scale and specific procedures used. - What are the advantages of using closed-loop hydrocarbon extraction systems?

Closed-loop systems are safer, more efficient, and environmentally friendly as they recycle the solvents used in the extraction process. - Do you offer any assistance with the setup of hydrocarbon extraction equipment?

Yes, we provide comprehensive setup assistance and training to ensure your equipment is installed and operated correctly.

Join Our Newsletter

Stay ahead in the world of extraction technology by signing up for Root Sciences’ exclusive quarterly newsletter. Get the latest insights, trends, and innovations delivered directly to your inbox!