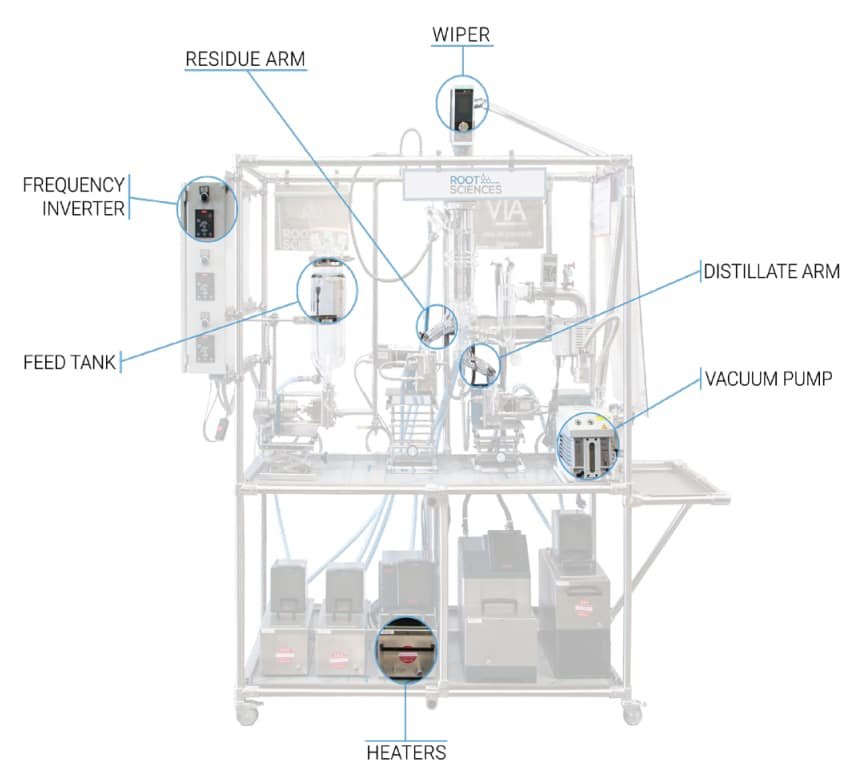

VK 200-40 RS Wiped-Film Short Path Distillation System

Key Features

Throughput Capability: 40,000 mL/h

Optimal Yields and Potency: Finished distillate contains up to 99% total cannabinoids

Independent Degassing Stage: Separate degassing stage ensures optimal processing regardless of flow rate and feedstock quality

Fully Jacketed System: Heated from start to finish, negating the use of heating tape or heat guns to keep product moving through the system

True Continuous Feed: Unique design allows uninterrupted operation through continuous feed into the system and dispenses finished product to atmosphere without breaking vacuum

Fully Pump-Driven Operation: Integrated pumps provide full operator control over feed and discharge rate instead of relying on gravity fed systems

GMP Ready: Equipment can be customized according to your URS to meet any local or international GMP requirements

Expert On-Site Training: Instructions for operation of equipment and proprietary parameters for producing distillate are included with purchase

Wiped-Film Short Path Distillation Equipment

Root Sciences’ wiped-film molecular distillation plants are specifically intended for the processing of cannabis and hemp crude oil, with honest and accurate throughput/yield rates reflecting that. Designed and manufactured by VTA of Germany, these machines are expertly engineered to produce distillate that can be used in a wide variety of products commonly found on the market today.

Equipment is available to suit a range of operations, from small-scale labs focusing on the recreational THC market, all the way up to large-scale hemp processing facilities focusing on industrial CBD production, and everything in between.

The VTA VK 200-40 is the flagship offering in the VTA line up and is the industry standard for industrial-scale hemp processing facilities. It is a dual-stage short-path distillation plant with a degassing stage for processing winterized and decarboxylated cannabis or hemp oil derived from extraction methods using CO2, light hydrocarbon, or cold ethanol. The VK 200-40 is designed to be operated in semi-automatic mode for continuous production in state-of-the-art facilities.

Technical Specs

| Throughput | 40,000 mL/h |

| Distillate Yield (per 8 hr. shift) | 280 L |

| Evaporator Surface Area | 0.4 m² |

| Power Requirements | 3Φ 400 V, 60 Hz, 100 A |

| Stages | Dual |

| Dimensions (L x W x H) | 25.6’ x 6.9’ x 12.9’ |

| Weight (gross) | 6,000 kg |

| Certification | UL ready (all necessary individual components are UL listed) |

| Warranty | 1 year (excluding glass and vacuum system) |

| Materials Used | 316 stainless steel, graphite wipers |

ROI/Payback Period

| Material |

Cannabis |

Hemp |

Cannabis |

Hemp |

| Daily Processing Time |

8-hour (one shift) |

24-hour continuous (three shifts) |

||

| Daily Distillate Yield |

280 L |

1,050 L |

||

| Daily Distillate Value |

$2.28M |

$1.23M |

$6.85M |

$3.69M |

| Payback Period |

1.6 days |

3.4 days |

0.5 days |

1.1 days |