XStream Lab Homogenizer 2000 for Cannabis Nanoemulsion

TECHNICAL DATA

| Model | XStream |

|---|---|

| Max Flow Rate | 10.8 L/h |

| Production Rate (10 mg servings/h) |

16k (flavorless) 18k (clear) |

| Pressure | 2,000 bar |

| Motor Power | 1.85 kW |

| Electrical Options | 3Φ 200 V, 50 Hz 3Φ 220 V, 50-60 Hz 3Φ 400 V, 50 Hz 3Φ 460 V, 60 Hz |

| Required Utilities | Compressed air (10 bar) |

| Feeding Hopper Volume | 0.4 L |

| Minimum Sample Volume | 30 mL |

| Dimensions (LxWxH) | 940 x 617 x 640 mm |

| Weight | 170 kg |

Optional Upgrades Include:

– 2 L jacketed feeding hopper with pneumatic pusher

– Heat exchanger for product outlet

– Temperature sensors for inlet/outlet

– Documentation for cGMP/CFR 21/GAMP

– IKA T-25 high shear mixer package

Key Features

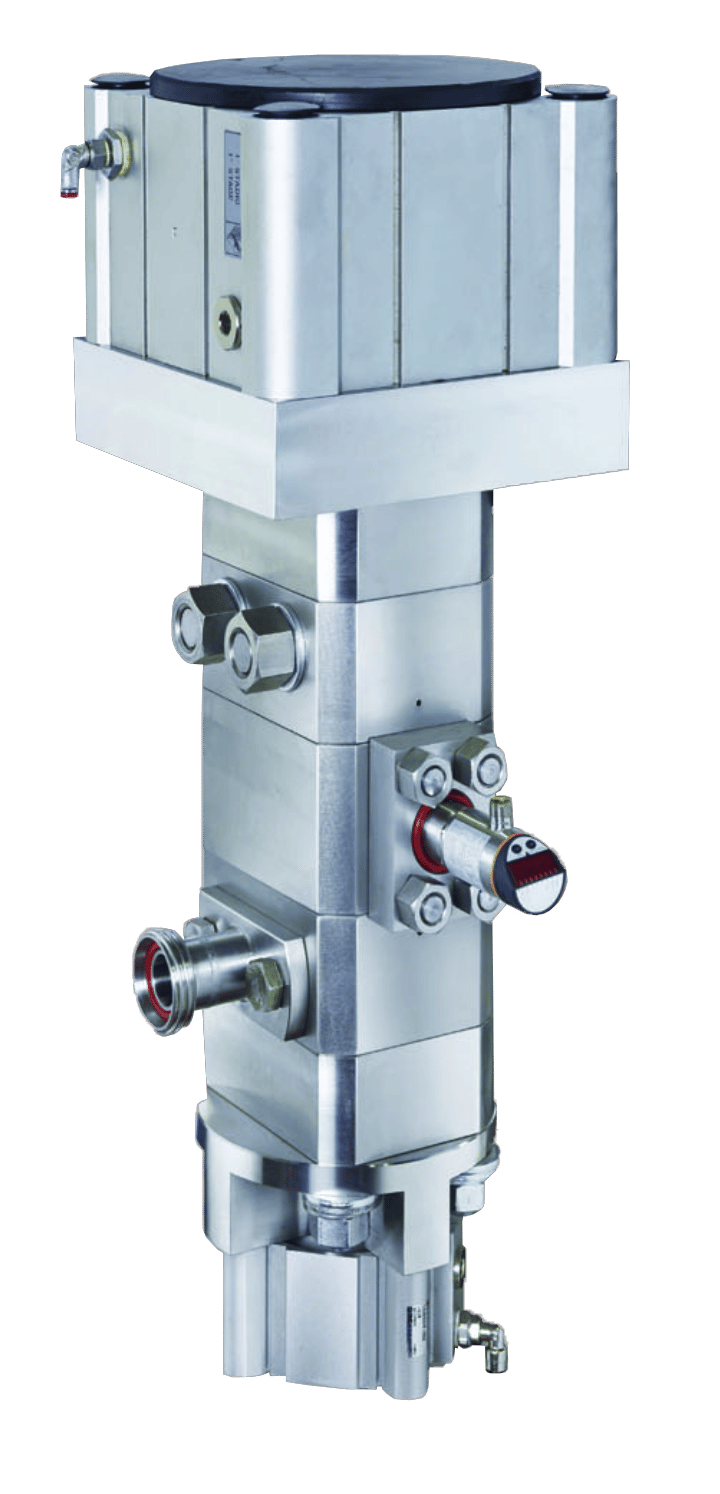

- NiSoX-Valve technology produces incredibly fine nanoemulsions with fewer passes than conventional equipment

- Pneumatically regulated homogenizing valves allow precise, automatic, and continuous operation

- Flow rates up to 10.8 L/h, produces up to 144k 10 mg servings per 8-hour shift

- Produces water-soluble cannabinoid nanoemulsions that are easily added to beverages and edibles

- Benefits include enhanced shelf-life, improved bioavailability, and faster uptake

- Begin production immediately with Root Sciences’ proprietary clear, flavorless, or high-load formulations

- Clean-In-Place (CIP) and simple preventative maintenance procedures

- Proven homogenization technology used in beverage, chemical, and pharmaceutical processing

Advantages of Products Manufactured with Nanoemulsions

Hemp and cannabis nanoemulsion-based products provide substantial benefits compared to traditionally manufactured edibles and beverages.

The proprietary nanoemulsification and micronization technologies greatly increase the bioavailability of cannabinoids. This creates a substantially more stable product that is highly resistant to separation. Products created with nanoemulsions take effect more quickly than traditional infused edibles and deliver more consistent and enjoyable experiences for consumers.

High-Pressure Homogenization

Nanoemulsions are stable dispersions of two immiscible liquids, such as cannabis oil and water. The tiny droplets of oil are typically between 20 and 600 nanometers in diameter and are stabilized by a thin film of surfactants.

First, a coarse emulsion with large droplet sizes is created through the use of a high shear mixer. Then the coarse emulsion is passed through a GEA High Pressure Homogenizer several times. This process can easily be integrated into a large scale manufacturing line.

A breakthrough in engineering, the newly developed NiSoX homogenizing valve replaces the previous generation Re+Valve. Completely redesigned from the ground up, the NiSoX-Valve boasts superior performance and efficiency by optimizing the flow-dynamic effects generated inside the device. NiSoX homogenizers enable more rapid production of nanoemulsions, with a smaller average particle size and a tighter particle size distribution – leading to enhanced stability and more rapid onset.